2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

In the realm of manufacturing and design, chrome plating has emerged as an essential technique, not only for enhancing the durability of surfaces but also for elevating their aesthetic appeal. As the industry progresses towards 2025, the adoption of advanced chrome plating methods is set to revolutionize the way we perceive metallic finishes. Industry expert Dr. Richard Harlow, a leading authority on surface treatments, asserts, "The future of chrome plating lies in its adaptability and the innovative techniques that significantly extend the life and luster of metal products."

The implications of these emerging chrome plating techniques extend beyond mere aesthetics. They promise improved corrosion resistance, longevity, and a visually striking appearance that can meet the evolving demands of modern consumers. As manufacturers strive to align their products with the highest standards of quality and design, understanding the latest trends in chrome plating becomes critical. With advancements in technology and an emphasis on sustainability, the chrome plating industry is poised to deliver solutions that are both environmentally friendly and economically viable. Embracing these top chrome plating techniques will not only enhance product performance but also solidify brands' positions in an increasingly competitive market.

Overview of Chrome Plating Techniques for 2025

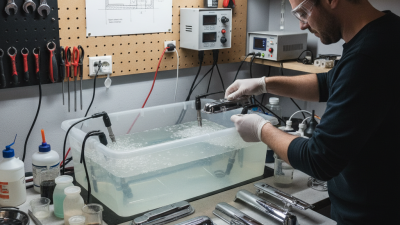

The chrome plating landscape in 2025 is set to witness significant advancements that focus on enhancing both durability and aesthetics. Technological innovations have led to the development of advanced electroplating techniques, which utilize environmentally friendly solutions while maintaining high-quality finishes. These new methods improve adhesion and corrosion resistance, resulting in long-lasting chrome coatings that can withstand harsh conditions. The integration of smart technologies in plating processes also allows for real-time monitoring and adjustments, ensuring uniformity and precision.

Additionally, aesthetic considerations have evolved, with designers seeking to create more versatile and appealing finishes. Innovative techniques such as dual-layer plating and matte chrome applications are becoming increasingly popular, offering customizable options for various industrial and decorative uses. This trend not only enhances the visual appeal of chrome-plated items but also opens new avenues for creative design in automotive, furniture, and consumer goods. As manufacturers adapt to these advancements, the overall quality and attractiveness of chrome-plated products are expected to significantly improve.

Advancements in Chrome Plating Technology

Advancements in chrome plating technology have revolutionized the way we enhance durability and aesthetics in various industries. Among these advancements, the introduction of several innovative techniques has significantly improved the efficiency and quality of the plating process. For instance, the development of high-velocity oxygen fuel (HVOF) spraying has enabled a more uniform and dense coating, providing superior adhesion and resistance to wear and corrosion. This method not only extends the lifespan of the plated surfaces but also enhances their visual appeal.

Another significant advancement is the use of environmentally friendly chrome plating methods. Traditional chrome plating processes often involve harmful chemicals, but recent innovations have focused on reducing the environmental impact. Techniques such as trivalent chromium plating have emerged as viable alternatives, offering comparable durability and aesthetics while minimizing toxic waste. Moreover, advancements in automation and precision control systems help achieve more consistent results, further pushing the boundaries of chrome plating technology towards both resilience and visual excellence. These developments not only meet the growing demands of industrial applications but also align with sustainability goals, making chrome plating a leading choice for manufacturers aiming to improve their overall product quality.

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

| Technique | Enhanced Durability | Aesthetic Improvement | Application Areas | Sustainability Factor |

|---|---|---|---|---|

| Electrolytic Chrome Plating | High resistance to wear and corrosion | Bright and reflective finish | Automotive, decorative, and industrial parts | Moderate, energy-intensive process |

| Hard Chrome Plating | Excellent surface hardness, prolongs lifespan | Can be polished to a very smooth finish | Machinery, hydraulic components | High, improves part longevity |

| Thin Dense Chrome Plating | Increased durability with lower thickness | High gloss and low friction surface | Aerospace, automotive, and precision components | High, less material usage |

| Vacuum Chrome Plating | Superior adhesion and corrosion resistance | Fine finish with a variety of colors | Consumer goods, home decor | Very High, minimal waste |

Durability Enhancements through Modern Plating Methods

The landscape of chrome plating techniques has evolved significantly, particularly in enhancing durability through modern methods. Research indicates that advanced chrome plating processes, such as hard chrome plating and decorative chrome plating, have shown to increase resistance to corrosion and wear by up to 30% compared to traditional methods. These enhancements not only improve longevity but also maintain the aesthetic appeal of plated surfaces, driving demand across various industries such as automotive, aerospace, and manufacturing.

Utilizing techniques like electroplating with improved power density can lead to smoother finishes, reducing stress points that often contribute to chipping and peeling. According to a recent industry report, implementing sophisticated surface treatment technologies has resulted in a 50% reduction in surface defects, extending the service life of chrome-plated components. This not only minimizes maintenance costs but also enhances performance in demanding environments.

**Tip:** When selecting a chrome plating method, consider the specific environmental conditions your components will face. For parts exposed to moisture or chemicals, opt for hard chrome plating for superior corrosion resistance.

**Tip:** Regular inspection and maintenance of chrome-plated surfaces can further extend their life. Applying protective coatings or wax finishes can shield them from scratches and environmental factors.

Aesthetic Improvements in Chrome Plating Finishes

The aesthetic improvements in chrome plating finishes have become a focal point in modern manufacturing, as industries seek to enhance both the visual appeal and functional qualities of their products. Innovative techniques such as multi-layer plating and the application of specialized coatings are revolutionizing the way chrome-plated items look and feel. These advancements allow for a broader palette of colors and textures, transforming traditional dull metal surfaces into vibrant, eye-catching components that attract attention and elevate design standards.

In addition to visual enhancements, these modern chrome plating techniques provide protective features that extend the lifespan of products. By utilizing high-performance materials and advanced application methods, the finishes resist tarnishing, scratching, and corrosion. This not only maintains the shiny appearance but also ensures that the aesthetic qualities remain intact over time, thus enhancing the overall durability of the products. The integration of these aesthetic improvements with functional benefits reflects the evolving demands of consumers who seek both style and performance in chrome-plated items.

Environmental Considerations in Chrome Plating Processes

The chrome plating industry is increasingly focusing on environmental considerations as sustainability becomes a paramount concern across various sectors. Traditional chrome plating processes often involve harmful chemicals and generate toxic waste, posing a significant risk to both human health and the environment. Consequently, companies are now adopting more eco-friendly methods, such as trivalent chromium plating, which reduces the reliance on hexavalent chromium—a known carcinogen. This innovative approach not only enhances worker safety but also minimizes environmental impact by producing less hazardous waste.

Moreover, advancements in technology have led to the development of closed-loop systems that recycle and purify the chemicals used in the plating process. These systems significantly decrease water and energy consumption, making the entire operation more sustainable. Additionally, by investing in research and development, the industry is exploring alternatives to harmful substances, such as using biodegradable materials and greener processes that still meet the high standards required for durability and aesthetics. By prioritizing environmental considerations, chrome plating techniques are evolving to protect natural resources while delivering high-quality and visually appealing finishes.

Related Posts

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

2025 Top Guide to Cobalt Plating Techniques and Applications

-

What is Decorative Plating and How Does it Enhance Product Aesthetics

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

Top 10 Tips for Successful DIY Chrome Plating at Home