Best 10 Benefits of Copper Chrome Plating for Industrial Applications?

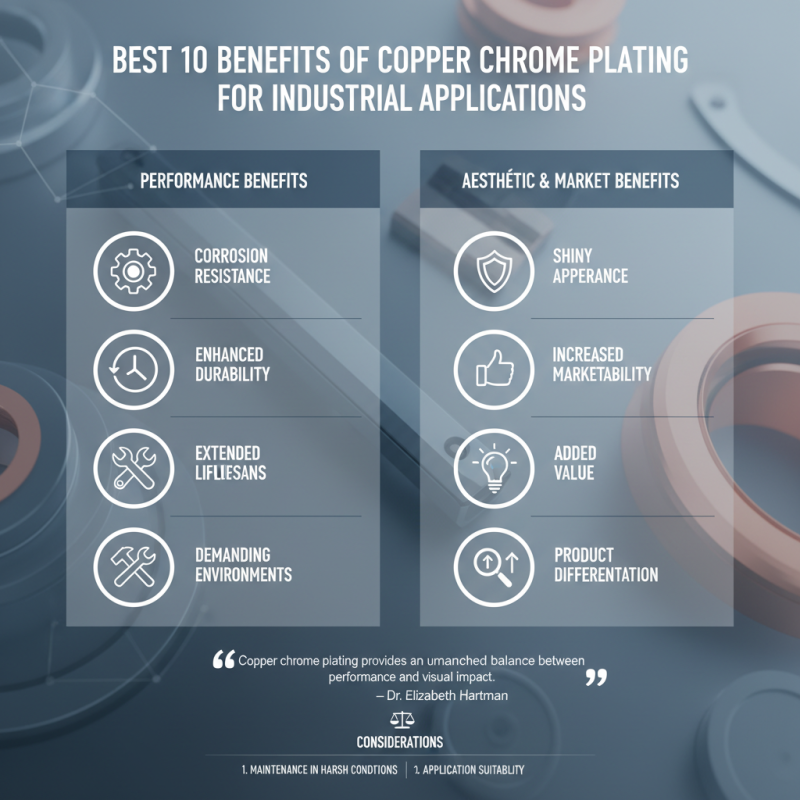

In the world of industrial applications, the importance of copper chrome plating is often understated. It enhances durability and aesthetic appeal, especially in demanding environments. According to renowned plating expert Dr. Elizabeth Hartman, “Copper chrome plating provides an unmatched balance between performance and visual impact.” This statement resonates with many industries seeking reliable solutions.

Copper chrome plating effectively protects components from corrosion, extending their lifespan significantly. The shiny appearance also adds value, enhancing the overall marketability of products. However, not every application benefits equally from this technique. Some industries may overlook the potential risks, like the need for more frequent maintenance in harsh conditions.

This balance of benefits and challenges makes copper chrome plating a topic worth exploring. As industries evolve, understanding these advantages is crucial. Organizations must reflect on how they implement this plating process in their projects and the long-term implications of their choices.

Overview of Copper Chrome Plating in Industrial Applications

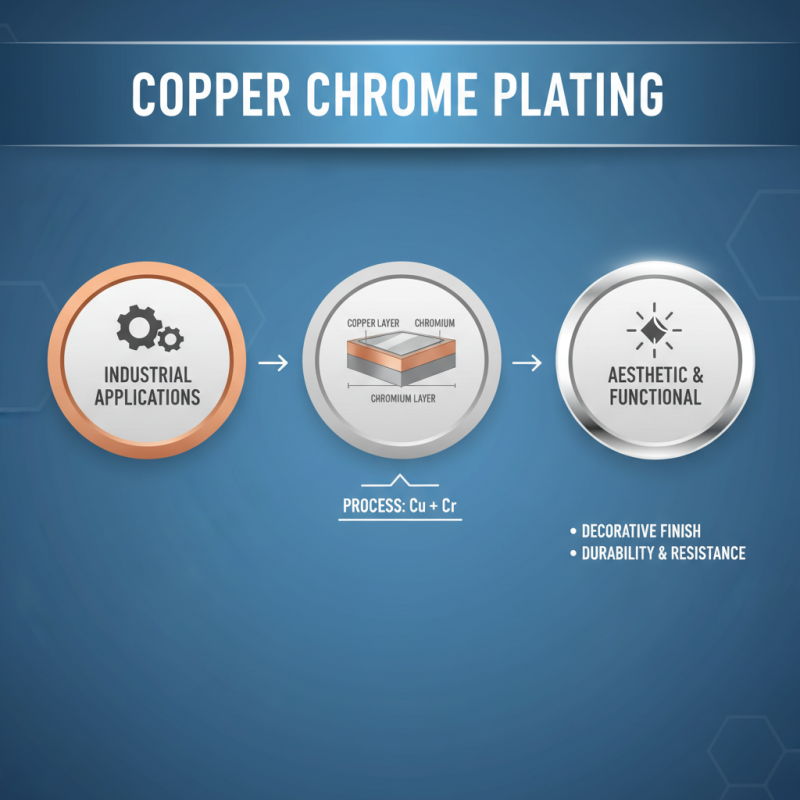

Copper chrome plating is gaining traction in various industrial applications. This process involves applying a thin layer of copper followed by chromium. The result is a surface that is both aesthetically pleasing and highly functional. The bright, reflective finish is often desired for decorative purposes, but that’s just the beginning.

In industrial settings, copper chrome plating offers enhanced corrosion resistance. This protection is vital for components exposed to harsh environments. Additionally, the plating improves wear resistance. Parts that undergo frequent friction benefit significantly. However, achieving a uniform layer can be challenging. Any inconsistency may lead to unexpected failures.

Moreover, copper chrome plating has excellent thermal and electrical conductivity. This feature makes it ideal for electrical contacts and connectors. Keeping production costs low while maintaining quality is a constant struggle. Some techniques may require re-evaluation for better performance. Balancing efficiency and outcome is essential for successful applications.

Corrosion Resistance: How Copper Chrome Plating Protects Metal Surfaces

Copper chrome plating offers significant benefits for industrial applications, particularly in enhancing corrosion resistance. This plating technique creates a durable barrier against moisture and various chemicals. Metal surfaces coated with copper chrome experience much slower deterioration. Without this protection, metals would corrode rapidly, leading to costly repairs and replacements.

Additionally, copper chrome plating provides a layer of shine and aesthetic appeal. However, it’s essential to ensure a proper application process. If improperly done, the benefits may not fully manifest. In some cases, uneven plating could lead to exposed areas, which are susceptible to corrosion. Hence, attention to detail during the plating process is crucial. Regular maintenance and inspections can help identify any potential failures early on.

The longevity of coated metal is undeniable, yet some industries may overlook periodic checks. Over time, a buildup of contaminants could compromise the integrity of the plating. Selecting the right environment and conditions for these applications is another aspect that shouldn’t be ignored. While copper chrome plating provides essential protection, awareness of ongoing care remains vital to maintaining its advantages.

Enhanced Durability: Longevity Benefits of Copper Chrome Coatings

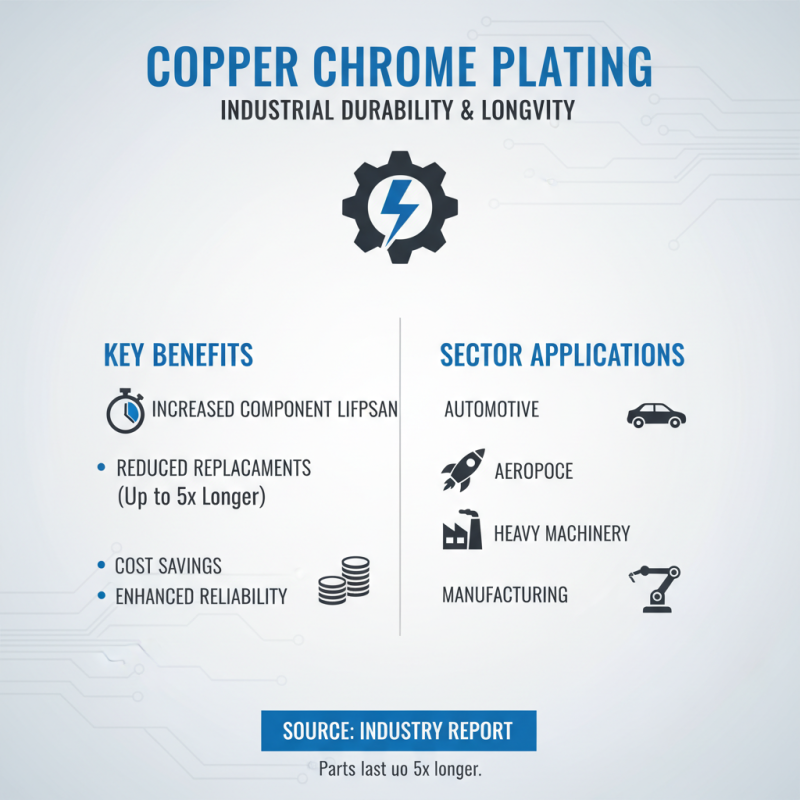

Copper chrome plating offers remarkable durability for industrial applications. This process increases the lifespan of components, reducing the need for frequent replacements. According to a recent industry report, parts with copper chrome coatings can last up to five times longer than those without. This longevity is crucial in industries such as automotive and aerospace, where equipment failure can lead to costly downtimes.

The hardness of the coating is another significant factor. Copper chrome plating provides a surface that withstands wear and tear effectively. It demonstrates resistance to corrosion and oxidation, essential for components exposed to harsh environments. A study showed that components with this coating suffered 30% less degradation over time compared to uncoated counterparts. However, companies must consider the initial cost of this treatment. While the upfront expense may appear high, the long-term savings and reduced maintenance can justify the investment.

Despite its benefits, not all applications may see the same results. The effectiveness of copper chrome plating can vary depending on the substrate material and environmental conditions. It's vital to evaluate the specific needs of each application. Not every use case will yield the desired performance levels. Understanding these variables is key to maximizing the benefits of copper chrome coatings.

Improved Wear Resistance: Performance Advantages in Heavy-Duty Use

Copper chrome plating offers significant benefits for heavy-duty industrial applications. One of the foremost advantages is improved wear resistance. This type of plating significantly enhances the durability of various components. It reduces friction, which is essential in heavy machinery. This results in longer service life for parts subjected to extreme conditions.

In heavy-duty use, wear and tear can lead to costly downtime. Copper chrome plating helps mitigate this risk. The coating forms a tough barrier that protects underlying materials. It can withstand high loads and abrasive environments. This makes it ideal for industries like mining and construction. However, achieving optimal results depends on surface preparation and application techniques. Imperfections can undermine performance. It's crucial to pay attention to these details. Regular inspections can also identify wear patterns, prompting necessary adjustments. This can further enhance the benefits of copper chrome plating.

Best 10 Benefits of Copper Chrome Plating for Industrial Applications

| Benefit | Description | Applications | Performance Impact |

|---|---|---|---|

| Improved Wear Resistance | Copper chrome plating enhances the surface hardness of components, reducing wear during heavy-duty use. | Machinery parts, automotive components | Increases lifespan and reliability |

| Corrosion Resistance | Offers excellent protection against various corrosive elements, extending the service life of parts. | Marine applications, chemical processing | Reduces maintenance costs |

| Low Friction | The plating provides a low-friction surface, improving efficiency in moving parts. | Bearings, pistons | Enhances overall machinery performance |

| Aesthetic Appeal | Offers a bright, shiny finish for decorative applications and components. | Consumer products, electronics | Increases product value |

| Thermal Conductivity | Copper chrome plating retains high thermal conductivity, useful in heat distribution applications. | Heat exchangers, cooling systems | Improves heat management |

| Increased Electrical Conductivity | Maintains high electrical conductivity, ideal for electrical contacts and circuits. | Electrical connections, wiring | Enhances electrical performance |

| Chemical Stability | Resistant to chemical reactions, ensuring long-term operation in harsh environments. | Chemical storage, processing equipment | Reduces risk of failure |

| Customizable Thickness | Thickness of plating can be adjusted to meet specific application requirements. | Customized industrial components | Tailored solutions for specific needs |

| Cost-Effective | Provides a low-cost solution for enhancing the performance of parts without extensive redesign. | Manufacturing components | Maximizes ROI on components |

Cost-Effectiveness: Economic Benefits of Copper Chrome Plating for Industries

Copper chrome plating offers several economic benefits for industries. This technique combines the excellent conductivity of copper with the durability of chrome. As a result, companies can improve their product longevity while reducing maintenance costs. According to a recent industry report, businesses that utilize copper chrome plating can see a reduction in repair and replacement expenses by up to 30%. This is a significant saving that many manufacturers overlook.

Moreover, the initial investment in copper chrome plating often pays off quickly. The solid layer protects against corrosion and wear. Some studies indicate that components treated with copper-chrome coatings can last 50% longer than untreated versions. Industries often face challenges with downtime and lost productivity. The extended lifespan translates to less frequent replacements and minimal process disruptions. However, companies should consider the variability in surface preparation and quality control. These factors can affect the ultimate performance of the plating.

While the benefits are evident, attention to detail is essential. Neglecting proper plating techniques might lead to uneven coatings. This can result in unexpected failures, ultimately negating the cost savings. Companies need a balanced approach. They should focus on investing in high-quality plating processes to fully leverage the economic benefits copper chrome plating offers.

Benefits of Copper Chrome Plating for Industrial Applications

Related Posts

-

2026 Best Industrial Chrome Plating Techniques for Enhanced Durability?

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know

-

2025 Top Industrial Chrome Plating Techniques Benefits and Applications

-

2025 How to Understand the Benefits of Chrome Plating for Your Projects

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices