Why is Industrial Hard Chrome Plating Important for Industries?

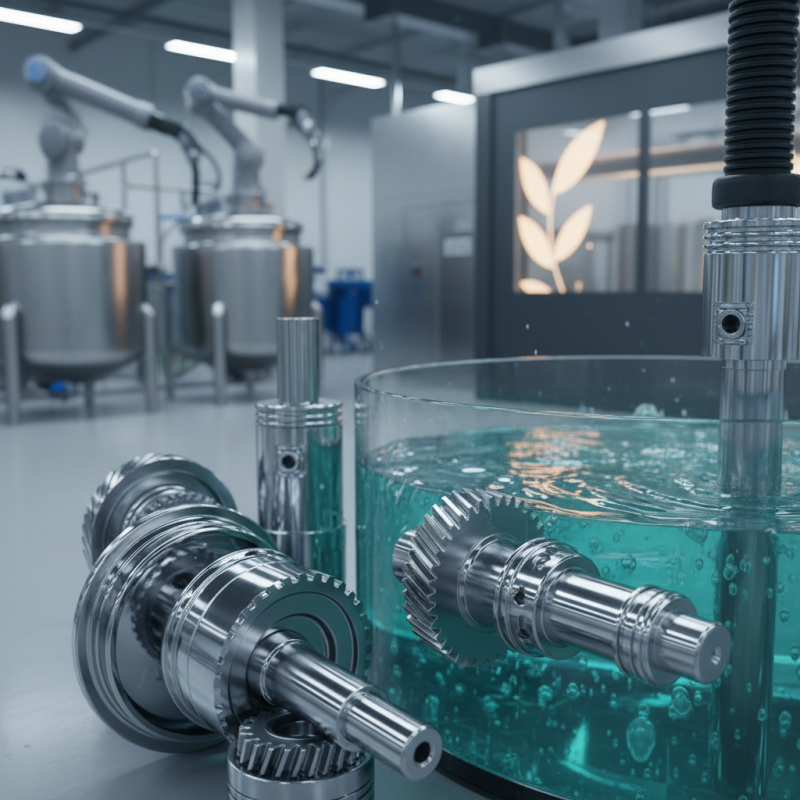

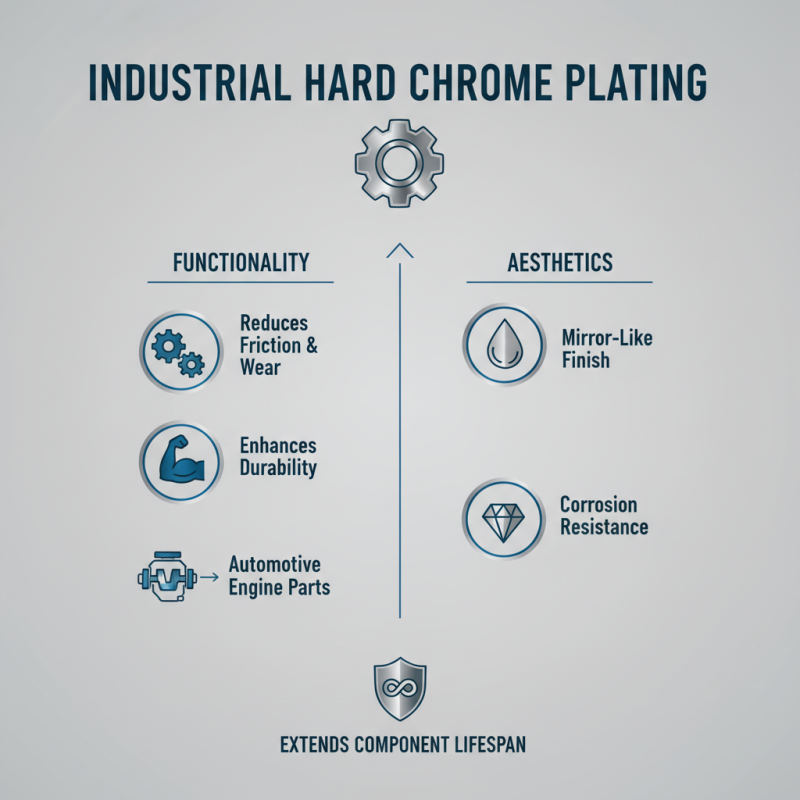

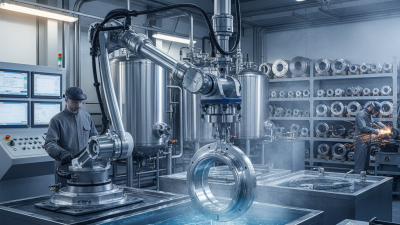

Industrial hard chrome plating serves a vital role in various sectors. It enhances the durability of components subjected to wear and tear. This process creates a robust surface layer that can withstand high-stress conditions. By improving resistance to corrosion, it ensures longevity in harsh environments.

In industries like aerospace and automotive, components face significant challenges. Industrial hard chrome plating provides a solution that helps maintain performance. It reduces friction, leading to improved efficiency. As a result, machinery operates smoothly for extended periods.

However, the process is not without its drawbacks. Environmental concerns arise from the chemicals used. Companies must prioritize safety and compliance. Balancing the benefits with sustainability remains a challenge. Continuous improvement is essential in industrial hard chrome plating practices.

Importance of Hard Chrome Plating in Enhancing Component Durability

Hard chrome plating plays a crucial role in enhancing the durability of components across various industries. This process involves applying a layer of chromium to surfaces, significantly improving wear resistance. It protects parts from friction, which is vital in heavy machinery settings.

Many components, like valves and cylinders, endure harsh conditions. Without hard chrome plating, these parts deteriorate quickly. The increased lifespan of components translates to reduced maintenance costs. Companies experience fewer breakdowns, leading to better productivity.

However, not all applications fully utilize hard chrome plating's benefits. Some industries still overlook its importance. Consequently, they face premature wear issues that could be avoided. Exploring different uses of this technology may reveal untapped potential for improved performance. Embracing hard chrome plating is about recognizing its value in maintaining and enhancing industrial components.

Why is Industrial Hard Chrome Plating Important for Industries? - Importance of Hard Chrome Plating in Enhancing Component Durability

| Component Type | Plating Thickness (microns) | Durability Improvement (%) | Common Applications | Average Lifespan Increase (years) |

|---|---|---|---|---|

| Hydraulic Cylinders | 20-50 | 30 | Construction, Manufacturing | 5 |

| Pump Shafts | 30-70 | 25 | Oil & Gas, Chemical Processing | 4 |

| Mold Plates | 40-100 | 40 | Automotive, Consumer Goods | 6 |

| Gear Components | 25-80 | 35 | Aerospace, Heavy Machinery | 5 |

| Rod Ends | 15-40 | 20 | Agricultural, Industrial Machinery | 3 |

Key Industries Benefiting from Industrial Hard Chrome Plating

Industrial hard chrome plating plays a crucial role in many key industries. It enhances the durability and performance of various components. For example, the automotive industry relies on hard chrome plating for engine parts. This process reduces friction and wear, leading to longer lifespans. It’s not just about functionality; aesthetics matter too. Chrome plating gives parts a shiny finish that is appealing.

In manufacturing, hard chrome plating is essential for tooling and machinery. It helps to protect against corrosion and improve surface hardness. Heavy machinery in mining and construction benefits greatly. Plated components can withstand harsh environments and heavy loads. However, there is always a need for careful assessment. Over-reliance on chrome plating can mask underlying issues in materials.

Aerospace and defense industries also see significant benefits. Components subjected to extreme conditions require top-notch durability. Chrome plating provides the necessary strength for such applications. Still, there are concerns about the environmental impact of the process. The balance between performance and sustainability is a topic worth exploring. Inclusion of eco-friendly alternatives is a growing consideration for future progress.

Statistical Overview: Cost Savings from Hard Chrome Applications

Industrial hard chrome plating offers significant advantages for various sectors. It's widely used to prolong the lifespan of machinery. This involves applying a thin layer of chrome to metal surfaces. The chrome adds hardness and resistance to wear.

Statistically, hard chrome applications can lead to substantial cost savings. A recent study revealed that businesses save up to 25% on parts replacement when using hard chrome. This can significantly reduce downtime and increase efficiency. Moreover, equipment that lasts longer minimizes the need for frequent investments.

Tips: Regular maintenance is crucial. Keeping plated surfaces clean can extend their life. Consider training staff to inspect and identify wear early. Monitoring parts can prevent unexpected failures and further costs. Remember, investing in quality plating pays off in the long run.

Environmental Considerations in the Chrome Plating Process

The chrome plating process is crucial for many industries. However, it raises significant environmental concerns. The chemicals used in plating can be hazardous. For instance, hexavalent chromium is toxic and carcinogenic. Proper disposal of waste is essential to minimize environmental impact.

Industries must adopt best practices for chrome plating. This includes using closed-loop systems to reduce waste. Implementing surface cleaning methods can also lessen contamination. Many facilities are exploring alternative, eco-friendly plating options. But the transition can be costly and complex.

Addressing these environmental issues requires ongoing effort. Regular audits of processes can identify areas for improvement. Employee training is vital to ensure safety protocols are followed. Balancing industrial needs with environmental responsibility can be challenging. The goal should be a sustainable approach that benefits both industries and the planet.

Environmental Impact of Chrome Plating Process

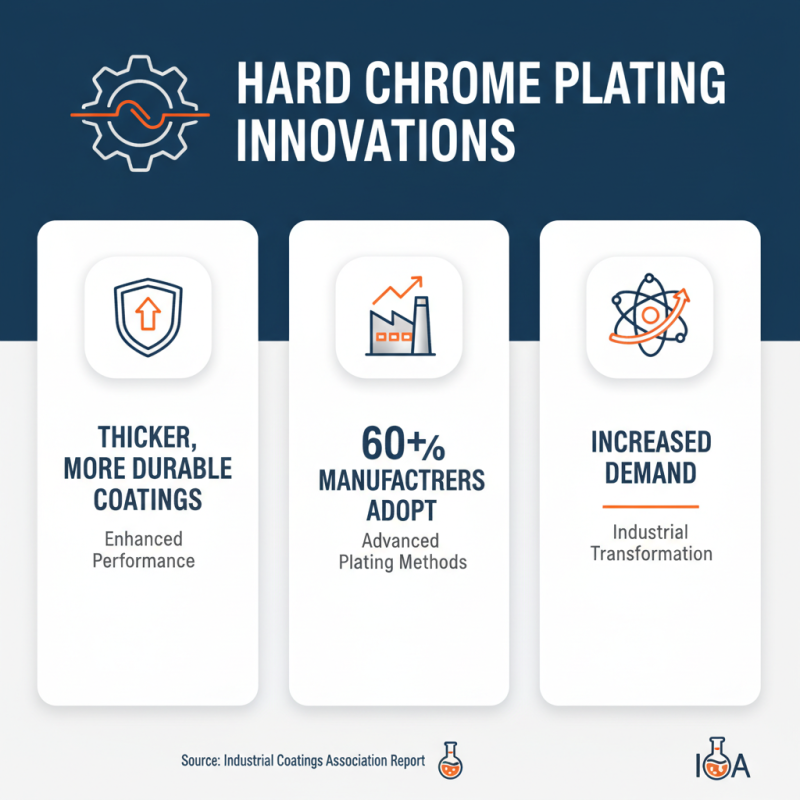

Future Trends: Innovations in Hard Chrome Plating Technologies

Innovations in hard chrome plating technology are transforming industries. For instance, new techniques enable thicker coatings with greater durability. A report from the Industrial Coatings Association shows that over 60% of manufacturers seek advanced plating methods. This shift highlights the increasing demand for enhanced performance.

The introduction of environmentally friendly alternatives is another crucial trend. Companies are exploring processes that minimize waste and harmful emissions. This is essential as regulations tighten around environmental impact. According to a recent study, up to 30% of manufacturers are aiming to adopt green plating technologies by 2025.

Despite these advancements, challenges remain. Many industries struggle to balance quality and cost. The need for skilled labor is critical, yet often overlooked. Research indicates that nearly 40% of firms report difficulty in finding qualified technicians. This skills gap may hinder progress in fully realizing the benefits of new technologies.

Related Posts

-

Top 10 Benefits of Industrial Hard Chrome Plating for Enhanced Durability

-

2025 Top Industrial Chrome Plating Techniques Benefits and Applications

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

Why You Should Know the Different Types of Chrome Plating for Your Projects