2026 How to Choose Chemicals Used in Chrome Plating for Your Project?

In the world of chrome plating, selecting the right chemicals used in chrome plating is crucial. Many projects hinge on the quality of these materials. Expert John Smith, a veteran in the plating industry, advises, "The choice of chemicals can define the durability of the finish." Understanding this can help you make informed decisions.

Chrome plating involves various processes and chemicals. Each chemical serves a specific purpose, whether it’s for cleaning, plating, or finishing. The right balance can create a durable, attractive coating. However, many overlook the importance of these chemicals. This can lead to a compromised result or even project failure.

It's essential to consider aspects such as environmental impact and safety. Some chemicals have hazardous properties that must be managed. Skipping this evaluation may result in unintended consequences. Therefore, a careful approach is needed when choosing chemicals used in chrome plating. This decision can determine the success of your entire project.

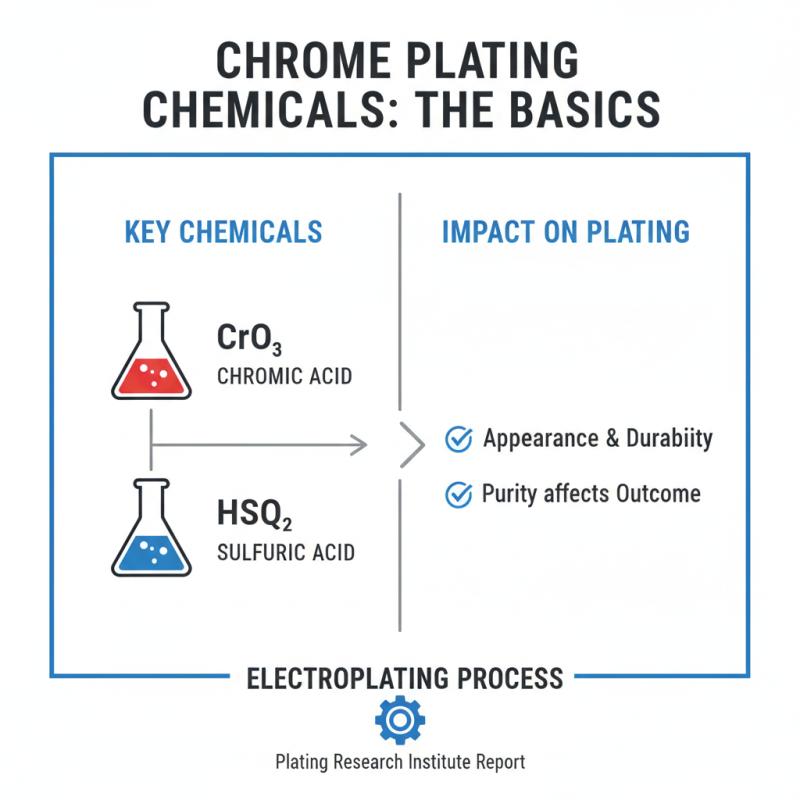

Understanding the Basics of Chrome Plating Chemicals

When choosing chemicals for chrome plating, understanding the basics is crucial. Chrome plating utilizes several key chemicals, including chromic acid and sulfuric acid. These chemicals play a vital role in the electroplating process, influencing the final product's appearance and durability. A report from the Plating Research Institute indicates that the purity of these chemicals can significantly affect the plating outcome.

Chromic acid is often the main component in chrome plating solutions. Its concentration levels typically range from 200 to 300 grams per liter. This range is important for achieving the right plating thickness and finish. Using lower-quality chemicals can lead to inconsistent plating results, resulting in pieces that may not meet industry standards. Additionally, regulations around hexavalent chromium present ongoing challenges that require careful selection and handling of chemicals.

The interaction between chemicals must be considered. Variations in temperature, pH, and current density can all impact how effectively the chemicals perform. A publication by the American Electroplaters and Surface Finishers Society emphasizes the importance of monitoring these factors closely. Failure to do so may result in defects such as poor adhesion or uneven coverage. Understanding these nuances is vital for any successful chrome plating project.

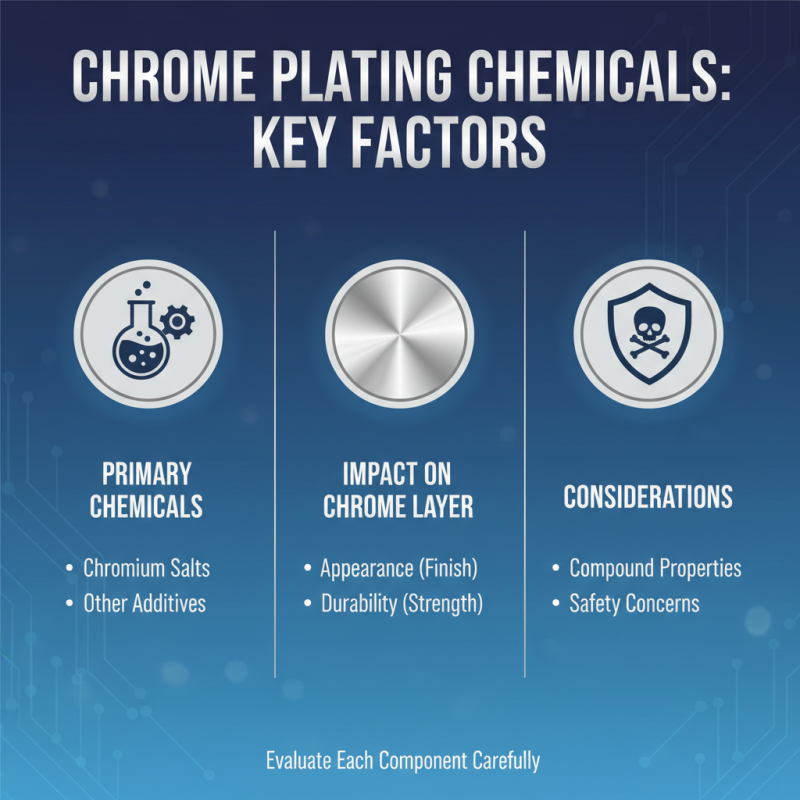

Evaluating the Types of Chemicals Used in Chrome Plating

When evaluating chemicals for chrome plating, several factors must be considered. The primary chemicals involved are chromium salts and other additives. These substances affect the final appearance and durability of the chrome layer. It's crucial to understand the role of each component. Not all chromium compounds have the same properties. Some may provide a better finish, while others may improve strength but create safety concerns.

Additionally, the pH level of the plating solution can impact the results. A balanced pH helps ensure even coating distribution. Uncontrolled pH can lead to uneven plating, producing unsatisfactory finishes. Consider the environmental impacts of the chosen chemicals as well. Some substances may be more eco-friendly than others. This choice can reflect on your project and its acceptance in the market.

Chemical selection is not straightforward. It requires careful thought and experimentation. You may find that a seemingly perfect combination doesn't yield the expected results. Adjustments may be necessary, leading to trial and error. Overlooking the suppliers' safety data sheets can also lead to missteps. Each chemical has distinct safety concerns, and understanding them is vital. Balancing quality, safety, and compliance is key for effective chrome plating.

Assessing the Environmental Impact of Chrome Plating Chemicals

When discussing chrome plating, environmental impact is crucial.

Chrome plating often involves hazardous chemicals. Hexavalent chromium

is one of the primary concerns. According to the Environmental Protection Agency (EPA),

this substance poses serious health risks, including cancer.

In fact, even short-term exposure can lead to skin and respiratory issues.

Many industries must consider these factors. Reports indicate that nearly 30% of all chrome plating facilities

struggle to meet environmental regulations. This raises questions about the safety measures in place.

Regular audits and monitoring plans are essential, but not all companies implement them effectively.

Some facilities lack the technology to mitigate toxic emissions, leading to potential soil and water contamination.

Moreover, there’s an ongoing debate about alternative chemicals.

While some substitutes exist, their effectiveness varies. For instance, trivalent chromium is less toxic

but may not provide the same finish quality. This compromise creates an ethical dilemma for manufacturers.

Balancing environmental responsibility with product performance requires careful consideration and ongoing evaluation.

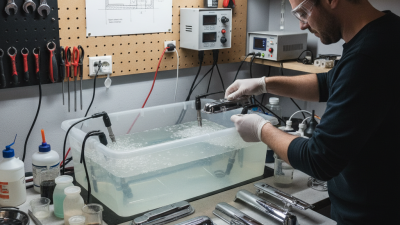

Safety Considerations When Handling Chrome Plating Chemicals

When dealing with chrome plating chemicals, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), exposure to chromium compounds can lead to serious health issues. Inhalation of hexavalent chromium, a common chemical in plating processes, is particularly dangerous. It can cause lung cancer and respiratory problems. Workers often overlook protective equipment due to the perceived safety of their environment.

Proper ventilation is crucial. Studies show that well-ventilated workspaces reduce the concentration of harmful fumes. Implementing fume extraction systems can effectively minimize exposure levels, keeping workers safer. Ensure that all staff receive training on handling chrome plating chemicals. Regular refresher courses can reinforce safe practices. A Culture of safety in the workplace can significantly reduce accidents.

Chemical spills, a frequent issue, highlight the importance of emergency preparedness. Having spill kits readily available is essential. Research indicates that companies with robust safety protocols experience fewer incidents. Employees should also know how to use these kits effectively. Safety data sheets (SDS) for all chemicals must be accessible. They provide crucial information on handling and first aid measures. Properly informed workers are key to maintaining a safe environment.

Safety Considerations When Handling Chrome Plating Chemicals

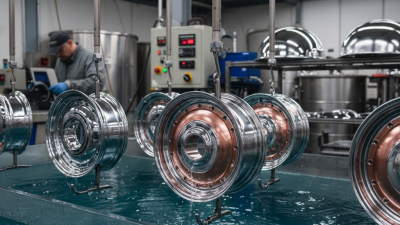

Choosing the Right Chemicals Based on Project Requirements

Choosing the right chemicals for chrome plating is crucial. Different projects require different chemical compositions. Understanding the specific needs of your project is the first step. For instance, a decorative chrome finish may need less robust chemicals than those used for industrial applications.

Consider the pH levels of the solutions. Balancing acidity and alkalinity impacts the plating quality. Look at the types of metals involved as well. Some substrates react uniquely to certain chemicals, causing uneven finishes. Always test small samples before committing to larger batches.

Environmental impact is another significant factor. Some chemicals are harmful to the environment. Assess the regulations concerning disposal and emissions. A good choice can enhance your project's success, while a poor choice can lead to costly repairs.

An aim for a process that is not only effective but also responsible - reflection on past mistakes can guide better decisions.

Related Posts

-

Top 10 Tips for Successful DIY Chrome Plating at Home

-

How is Chromium Used in Electroplating? Advantages and Applications Explained

-

How to Achieve Perfect Copper Chrome Plating Results?

-

Why is Industrial Hard Chrome Plating Important for Industries?

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

2026 Best Industrial Chrome Plating Techniques for Enhanced Durability?