10 Essential Tips for Successful Industrial Chrome Plating You Need to Know

Industrial chrome plating is a critical process that enhances the durability and aesthetics of a wide range of components across various industries. According to a recent report by Market Research Future, the global chrome plating market is expected to reach USD 18.6 billion by 2025, driven by increasing demand from automotive, aerospace, and manufacturing sectors. This underscores the importance of mastering the intricacies of industrial chrome plating, as it not only protects components from wear and corrosion but also improves their performance and appearance.

Industry expert Dr. John Smith, a leading authority in surface finishing technologies, emphasizes the significance of precise techniques in this field. He stated, "The success of industrial chrome plating hinges on a combination of proper surface preparation and precise application methods. Neglecting these factors can lead to suboptimal results and costly rework." This highlights the necessity for industry professionals to be aware of best practices to achieve successful chrome plating outcomes.

In this article, we will explore ten essential tips that can elevate your industrial chrome plating processes. By incorporating these best practices, businesses can ensure high-quality results that meet stringent industry standards, ultimately contributing to their competitiveness in the market.

Understanding Industrial Chrome Plating: An Overview of the Process

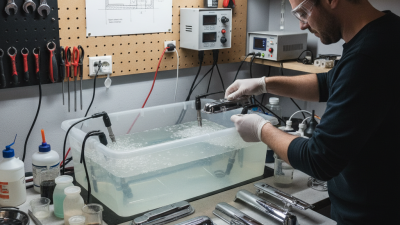

Industrial chrome plating is a sophisticated process employed to enhance the durability and appearance of various metal components. This technique involves applying a thin layer of chromium onto a substrate, typically steel or aluminum. The process begins with thorough cleaning of the surface to remove any contaminants, ensuring maximum adhesion of the chrome layer. Following this, the components are immersed in a plating bath containing a chromic acid solution, where an electric current is used to deposit chromium ions onto the surface. This electroplating method not only improves corrosion resistance but also provides an aesthetically pleasing finish.

After the plating process, parts are often subjected to additional treatments such as polishing and buffing to achieve a smooth and shiny surface. It is essential to monitor the thickness of the chrome layer throughout the process, as a uniform coating ensures optimal performance characteristics, including wear resistance and hardness. Moreover, the environmental aspects of chrome plating cannot be overlooked; proper waste management protocols must be adhered to, minimizing the impact on the ecosystem while maintaining the efficiency and effectiveness of the industrial chrome plating operation. Thus, a well-executed chrome plating process combines technical precision with responsible practices to achieve outstanding results.

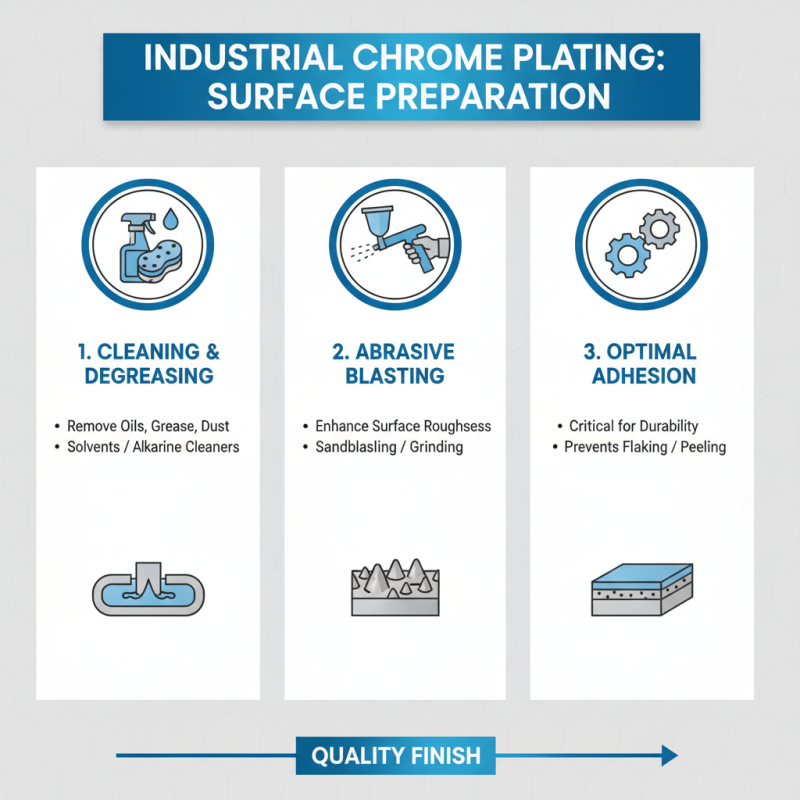

Essential Surface Preparation Techniques for Optimal Adhesion

Surface preparation is a critical step in the industrial chrome plating process, directly influencing the quality of adhesion and the durability of the finished product. To achieve optimal adhesion, surfaces must be free of contaminants such as grease, oil, dust, and oxides. A thorough cleaning using solvents or alkaline degreasers is essential to remove any residues that could impair the plating process. Furthermore, abrasive cleaning methods, such as sandblasting or grinding, can enhance surface roughness, providing additional mechanical bonding sites for the chrome plating to adhere more effectively.

Once the surface has been cleaned, it’s vital to maintain a controlled environment to prevent recontamination. Exposure to moisture or airborne particles can lead to oxidation or other surface defects. After cleaning and preparing the surface, applying a pre-plating treatment can further enhance adhesion. This may involve processes like activation through acid etching or the application of a suitable primer that creates a conducive interface for the chrome layer. By meticulously preparing the surface, manufacturers can ensure a stronger bond and improved performance of their chrome-plated components, ultimately leading to enhanced product longevity and success in the industrial market.

Choosing the Right Chrome Plating Equipment and Materials

When it comes to industrial chrome plating, selecting the right equipment and materials is crucial for achieving high-quality results. Investing in specialized chrome plating equipment tailored to your specific needs can significantly enhance efficiency and the durability of the finished product. Equipment such as rectifiers, plating tanks, and filtration systems should be chosen based on the scale of production and the types of items being plated. This foundational step ensures not only proper application but also contributes to the longevity and resilience of the chrome finish.

Another key aspect is the choice of materials used in the plating process. For effective results, utilize high-grade chemicals and substrates that complement your chrome plating operations. Ensure that the substrates are pretreated properly, as this can greatly influence adhesion and the overall quality of the chrome layer.

Tip: Always process materials in a controlled environment to prevent contamination that could compromise the plating.

Additionally, don’t overlook the importance of regular maintenance for your equipment and materials. Diligent care can prolong the lifespan of the machinery and keep the plating results consistent.

Tip: Implementing a routine inspection schedule can help identify potential issues before they escalate into costly repairs or rework.

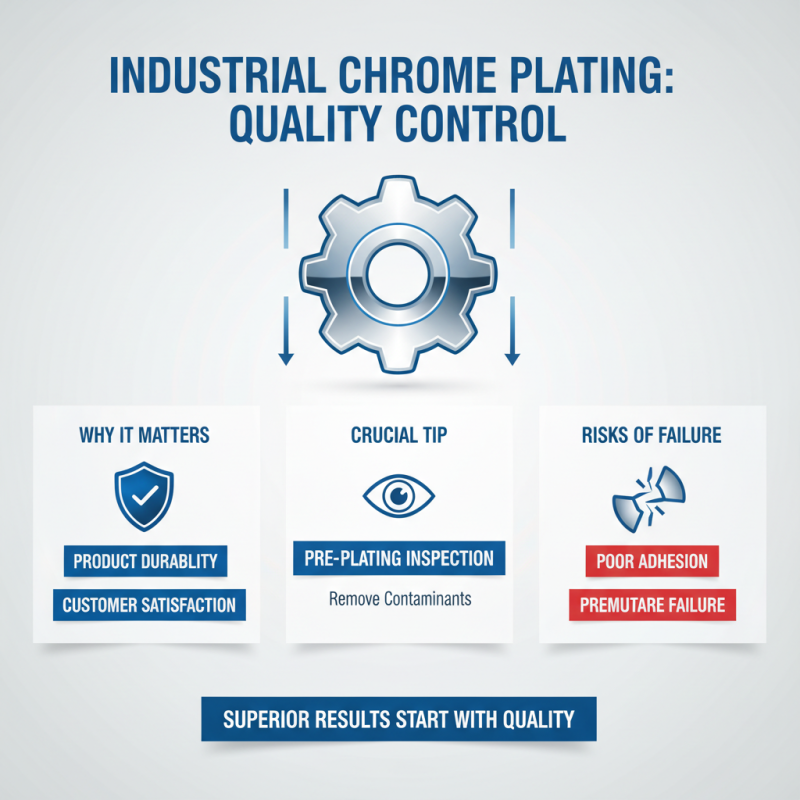

Quality Control Measures to Ensure Superior Plating Results

Quality control in industrial chrome plating is paramount to achieving superior results. Ensuring that every step of the plating process adheres to strict quality standards not only enhances product durability but also elevates overall customer satisfaction. One crucial tip for maintaining quality is to conduct thorough pre-plating inspections. This includes evaluating the surface preparation and ensuring all contaminants have been removed. Any imperfections on the substrate can negatively impact adhesion and ultimately lead to premature failure of the plating.

In addition to pre-plating inspections, implementing regular monitoring during the plating process is essential. This involves measuring bath chemistry, temperature, and current density to ensure consistency and optimal plating conditions. To achieve uniform thickness, it is important to rotate or reposition parts as necessary within the plating tank. A well-documented monitoring process will help identify any deviations early on, allowing for timely adjustments that maintain quality throughout production.

Final inspections and testing after plating completion serve as the last line of defense in quality assurance. Utilizing techniques such as visual inspections, thickness measurements, and adhesion testing can provide significant insights into the overall quality of the chrome plating. This comprehensive approach ensures that only the highest quality products are delivered, reinforcing the importance of stringent quality control measures in achieving successful industrial chrome plating.

Common Challenges in Chrome Plating and How to Overcome Them

Chrome plating is a popular process in various industrial applications, but it comes with its own set of challenges. One of the most common issues is surface preparation. If the substrate material is not cleaned and prepped properly, the adhesion of the chrome layer can be compromised, leading to flaking and premature wear. To overcome this, it is crucial to employ rigorous cleaning techniques, including ultrasonic cleaning or abrasive blasting, to ensure the surface is free of contaminants before plating.

Another challenge in chrome plating is ensuring a uniform coating thickness. Variances can occur due to changes in the electrical current or the geometry of the object being plated. To address this, consistent monitoring of the plating parameters is essential. Implementing a robust quality control process that includes regular thickness measurements and adjustments during the plating cycle can help maintain uniformity. This attention to detail not only enhances the durability of the chrome finish but also improves the aesthetic appeal of the final product.

Challenges in Chrome Plating and Their Impact

Related Posts

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

Top 10 Tips for Successful DIY Chrome Plating at Home

-

2025 Top Guide to Cobalt Plating Techniques and Applications

-

What is Decorative Plating and How Does it Enhance Product Aesthetics

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

Why You Should Know the Different Types of Chrome Plating for Your Projects