FAQS

: Common materials include gold, nickel, chrome, stainless steel, and polymers, each offering unique aesthetic and functional characteristics.

Decorative plating allows manufacturers to create an eye-catching finish that mimics more expensive materials, enhancing the luxurious look of products without high costs.

Decorative plating can be applied to various materials such as plastics, metals, and ceramics, and it allows for a wide range of textures and colors, expanding creative possibilities.

Key industries benefiting from decorative plating include automotive, electronics, and consumer goods, where aesthetics and protective benefits are crucial for product appeal.

By improving the visual appeal and mimicking expensive materials, decorative plating helps differentiate products in competitive markets, making them more attractive to consumers.

Decorative plating improves the aesthetic quality of vehicles and components while also offering durability, catering to consumer preferences for visually appealing automotive products.

Besides enhancing appearance, decorative plating prevents corrosion and wear, which is vital for consumer electronics where design influences purchasing decisions.

Manufacturers should research the types of finishes available and select techniques based on the desired outcome, durability, and the specifics of the product design.

Collaborating with suppliers who specialize in eco-friendly plating options can help manufacturers enhance sustainability and attract environmentally conscious consumers.

The global automotive decorative market is expected to reach USD 10.1 billion by 2025, reflecting the increasing consumer demand for aesthetically pleasing products.

Conclusion

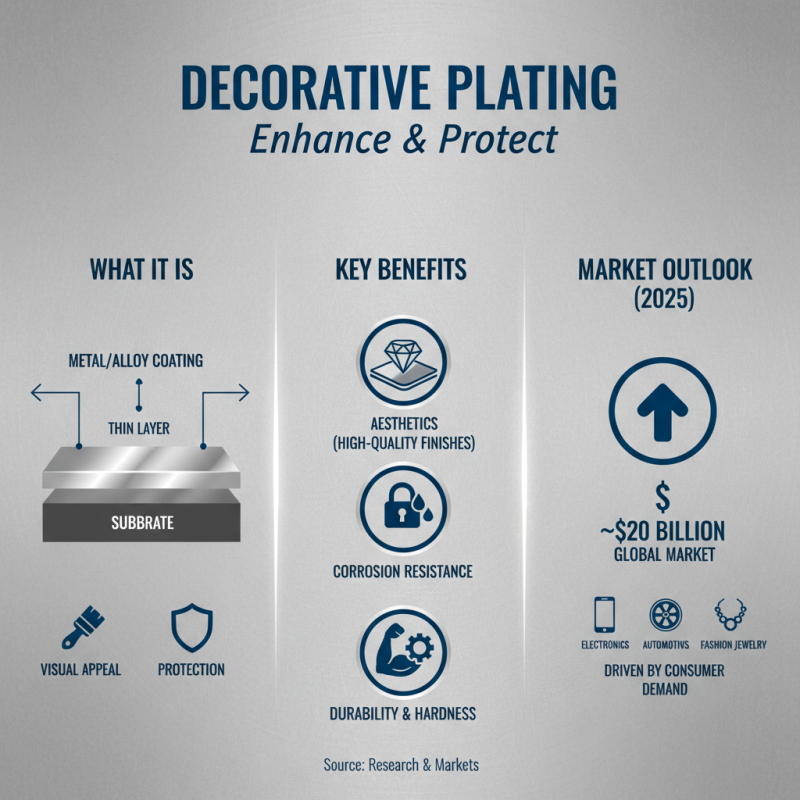

Decorative plating is a process that involves applying a thin layer of metal or alloy onto a substrate to enhance the visual appeal and functional properties of products. This technique is popular across various industries, as it allows for the customization of aesthetics while also providing protection against corrosion and wear. Common materials used in decorative plating processes include gold, silver, and nickel, each offering distinct benefits that cater to different design requirements.

The advantages of decorative plating in product design are numerous, including improved durability, enhanced aesthetic value, and the ability to achieve a specific finish that aligns with brand identity. Key industries such as automotive, electronics, and jewelry significantly benefit from decorative plating applications, as it enables them to create visually striking and resilient products. As technology advances, future trends in decorative plating are expected to focus on sustainability and innovative techniques, further enhancing product aesthetics while minimizing environmental impact.