2025 Top Guide to Cobalt Plating Techniques and Applications

Cobalt plating, a vital process in modern manufacturing, offers unique properties such as enhanced wear resistance, corrosion protection, and a polished finish. In the realm of surface engineering, experts like Dr. Emily Hart, a leading figure in the cobalt plating industry, emphasize its significance by stating, "Cobalt plating not only extends the lifespan of components but also plays a crucial role in improving performance across various applications." As industries continue to seek innovative solutions to enhance component durability and functionality, understanding the intricacies of cobalt plating techniques becomes essential.

This guide aims to provide a comprehensive overview of cobalt plating techniques and their various applications, which span automotive, aerospace, medical, and electronics sectors. By exploring advanced methods, challenges, and emerging trends within the cobalt plating landscape, this article seeks to equip professionals with the knowledge necessary to leverage this technology effectively. Embracing cobalt plating not only represents an investment in quality but also showcases a commitment to advancing industrial capabilities and meeting the demanding needs of today's marketplace.

2025 Overview of Cobalt Plating Techniques in Surface Finishing

Cobalt plating has emerged as a crucial technique in the surface finishing industry, providing enhanced wear resistance, corrosion protection, and aesthetic appeal to various components. According to a recent report by the Global Surface Finishing Association, the cobalt plating market is expected to grow significantly over the next decade, largely driven by the increasing demand in aerospace, automotive, and electronic applications. The report indicates that cobalt's unique properties, such as its hardness and resistance to oxidation, make it an ideal choice for components that are subjected to extreme conditions.

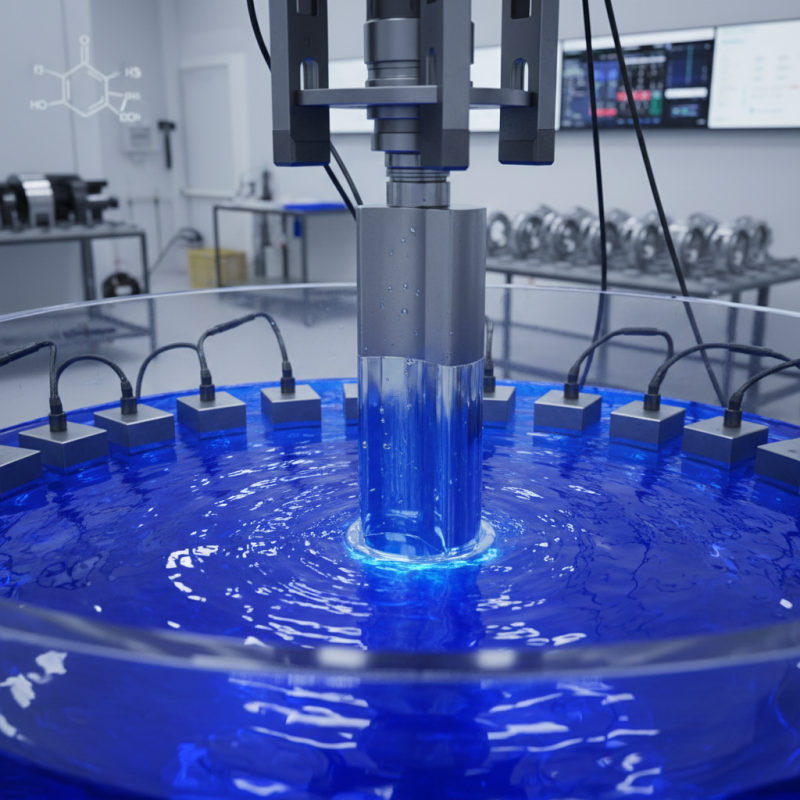

The techniques employed in cobalt plating range from electrolytic plating to electroless nickel-cobalt plating. Each method presents its advantages, with electrolytic processes providing thicker deposits and electroless methods offering uniform coverage on complex geometries. A 2023 industry analysis by Research and Markets highlighted that the electroless plating segment is expected to capture a substantial market share, due to its ability to coat non-conductive materials efficiently. Furthermore, innovations in cobalt alloy formulations are improving the performance characteristics of plated components, making them more suitable for high-stress environments.

As industries continue to evolve and the demand for high-performance materials increases, cobalt plating techniques are becoming more refined, enabling applications that were previously unattainable. With ongoing research and development, the future of cobalt plating looks promising, suggesting a pivotal role in the advancement of surface finishing technologies.

Key Benefits of Cobalt Plating in Various Industries and Applications

Cobalt plating has emerged as an essential technique in various industries, offering significant benefits that enhance the durability and performance of components. One of the primary advantages of cobalt plating is its exceptional resistance to wear and corrosion, making it ideal for high-stress applications such as aerospace and automotive components. This protective layer not only prolongs the lifespan of parts but also maintains their aesthetic appeal, making cobalt plating a popular choice for decorative finishes in the jewelry industry.

In the medical field, cobalt plating plays a crucial role in improving the biocompatibility of surgical instruments and implants. The non-reactive nature of cobalt ensures that these devices can operate within the human body safely and effectively. Additionally, cobalt plating can enhance the surface properties of tools, allowing for smoother interactions with biological tissues, which is vital in reducing friction and potential complications during medical procedures.

Tips for Cobalt Plating Application:

- Ensure proper surface preparation before plating; this is vital for achieving strong adhesion and optimal performance.

- Monitor the plating thickness closely to balance between protection and added weight, particularly in applications where minimizing mass is critical.

- Consider conducting a compatibility test with your specific substrates to identify any interactions that may affect the integrity of the plating.

Comparative Analysis of Cobalt Plating and Alternative Coating Methods

Cobalt plating is renowned for its hardness, wear resistance, and excellent magnetic properties, making it a superior choice for various industrial applications. In comparison to alternative coating methods like nickel plating or chrome plating, cobalt plating offers a unique blend of durability and aesthetic appeal. While nickel provides good corrosion resistance, it often lacks the hardness that cobalt delivers. Similarly, chrome plating is favored for its shiny finish but may not withstand the same wear and tear, especially in harsh environments. As industries continue to evolve, understanding these differences is crucial for selecting the right coating for specific applications.

Tips: When considering cobalt plating, evaluate the operational environment of your components. For example, if your parts will face extreme conditions, cobalt’s resilience may be the best fit. Additionally, always assess the compatibility of cobalt plating with other materials, as improper pairing can lead to complications during application.

Alternative methods, such as thermal spray coatings or ion plating, provide unique benefits but often fall short in certain areas when matched against cobalt plating. Thermal spray coatings may cover a larger surface area but can lack the uniformity and density that cobalt deposits can achieve. Ion plating may offer a thinner layer but generally does not provide the same level of hardness. Understanding these distinctions will enable manufacturers to make informed decisions that optimize performance and longevity in their products.

2025 Top Guide to Cobalt Plating Techniques and Applications

This chart compares the cost per square foot of various coating methods including Cobalt Plating, Nickel Plating, Zinc Plating, Chrome Plating, and Aluminum Anodizing. Cobalt plating stands out for its durability and wear resistance, making it a preferred choice for applications requiring high performance.

Industry Trends: Demand for Cobalt Plating in Aerospace and Automotive Sectors

The demand for cobalt plating in the aerospace and automotive sectors has surged in recent years, driven by the need for improved performance and durability of components. Cobalt plating provides a robust solution that enhances wear resistance, corrosion protection, and overall mechanical properties, making it an attractive choice for critical applications. With the aerospace industry focusing on lightweight yet strong materials to improve fuel efficiency, cobalt plating offers a way to extend the lifetime of components subjected to harsh environments and high-stress conditions.

In the automotive sector, the push for advanced safety features and performance improvements has led to increased interest in cobalt plating techniques. As manufacturers strive to create parts that withstand extreme wear while maintaining aesthetic qualities, cobalt offers a combination of hardness and polishability that is difficult to achieve with other materials. Moreover, as electric vehicles gain traction, the demand for specialized coatings in battery components and charging systems further propels the need for efficient cobalt plating processes. This trend reflects a broader industry movement towards using innovative surface treatments to enhance product lifecycle and reliability, positioning cobalt plating as a vital technology in both sectors.

2025 Top Guide to Cobalt Plating Techniques and Applications

| Application Sector | Cobalt Plating Technique | Key Benefits | Market Demand (2025 Est.) |

|---|---|---|---|

| Aerospace | Hard Cobalt Plating | High wear resistance, temperature stability | 15% Growth |

| Automotive | Electrolytic Cobalt Plating | Corrosion resistance, reduced friction | 10% Growth |

| Electronics | Cobalt-Phosphorus Alloy Plating | Enhanced conductivity, aesthetic finish | 8% Growth |

| Medical | Cobalt Chrome Plating | Biocompatibility, strength | 12% Growth |

Environmental Regulations Impacting Cobalt Plating Practices in 2025

In 2025, the landscape of cobalt plating practices is heavily influenced by stringent environmental regulations aimed at reducing ecological impact. These regulations emphasize the need for innovative methodologies that not only meet performance standards but also adhere to sustainability goals. Industries engaged in cobalt plating must navigate compliance with laws that mandate the reduction of harmful emissions and the responsible management of waste products. This involves adopting advanced techniques such as closed-loop systems and eco-friendly plating solutions, which minimize the release of hazardous substances into the environment.

Furthermore, the growing emphasis on sustainable practices is encouraging research and development in the field of cobalt plating. Companies are now investing in cleaner technologies that enhance efficiency while also aligning with regulatory requirements. This shift is guiding businesses to explore alternatives, such as non-toxic additives and techniques that consume less energy and resources. As environmental awareness rises, the focus on responsible cobalt plating not only addresses regulatory mandates but also contributes positively to brand reputation and consumer trust in an increasingly eco-conscious market.