How is Chromium Used in Electroplating? Advantages and Applications Explained

Chromium is used for electroplating to enhance the appearance and durability of metals. This process involves depositing a thin layer of chromium onto a metal surface. The shiny finish and corrosion resistance make it popular in various industries. Many products, from automotive parts to kitchen fixtures, benefit from this technology.

The advantages of chromium plating are significant. It offers a hard, protective layer that improves wear resistance. Additionally, its aesthetic appeal is undeniable. Chromium's reflective properties give items a polished and professional look. However, it's essential to consider environmental impacts and safety concerns associated with the plating process.

In industries like automotive and electronics, chromium's role is vital. Its application can be found in bumpers, wheels, and connectors. The versatility of chromium makes it a go-to choice for enhancing various products. Despite its benefits, the electroplating process requires careful handling and regulation. Balancing the advantages with safety is an ongoing challenge.

What is Chromium and Its Role in Electroplating?

Chromium is a chemical element with the symbol Cr. It has unique properties, making it vital in various industries. In electroplating, chromium serves as a high-quality finish for metals. This process involves depositing a thin layer of chromium onto a substrate. The result is a shiny, durable surface that resists corrosion and wear.

The role of chromium in electroplating is multifaceted. It enhances the aesthetic appeal of products, giving them a polished look. Additionally, it provides significant protection against rust and tarnishing. However, the electroplating process can be tricky. Achieving the right thickness and adherence requires careful control. Too thick a layer can lead to cracking, while too thin may not offer the needed durability. This balance is crucial for effective plating.

Electroplated chromium finds applications in various sectors, from automotive to decorative items. It's often used on car parts to give a sleek finish. However, the environmental impact of chromium is a concern. It's essential to consider how to manage waste materials effectively. Continuous improvements in techniques could help mitigate negative effects while maximizing the benefits of chromium in electroplating.

Chromium Usage in Electroplating: Advantages and Applications

The Electroplating Process: How Chromium is Applied

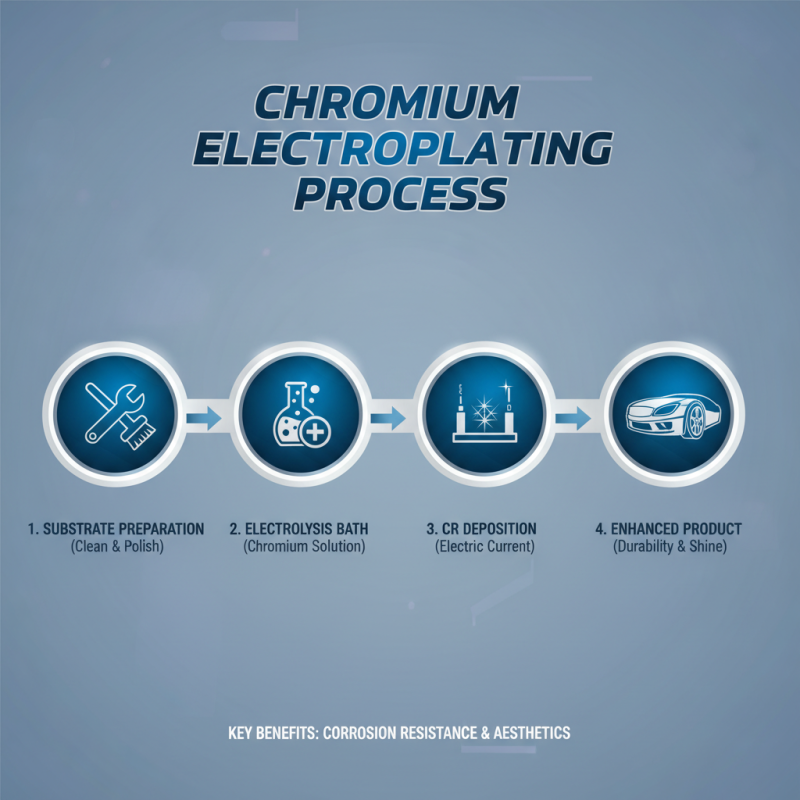

The process of electroplating with chromium is fascinating. It involves depositing a layer of chromium onto a substrate. This layer not only enhances appearance but also improves durability. The substrate must be carefully prepared before the application. Cleaning and polishing are crucial steps. They ensure the chromium adheres effectively and uniformly.

During the electroplating process, the substrate is immersed in a chromium solution. An electric current is passed through the solution. This causes chromium ions to migrate and form a thin layer on the substrate. The thickness can vary, depending on the desired finish. This process may not always be perfect; uneven deposits can occur. Such imperfections can affect the final outcome.

Chromium electroplating has diverse applications. It is widely used in automotive, aerospace, and electronics. It enhances corrosion resistance and aesthetic appeal. However, there are environmental concerns associated with chromium use. Balancing these factors requires continuous reflection and improvement in techniques. The potential for innovation in this field remains significant.

Advantages of Using Chromium in Electroplating

Electroplating with chromium offers several significant advantages. One major benefit is its exceptional hardness. Chromium coatings can achieve a hardness of around 1000 HV (Vickers Hardness), making them highly resistant to wear and tear. This is particularly valuable in industries where components face constant friction and abrasion.

Another advantage lies in corrosion resistance. Chromium plating creates a barrier that protects underlying metals from oxidation and contaminants. The corrosion resistance can be quantified; studies indicate chromium can extend the lifespan of metal components by up to 60%. This feature makes it useful in automotive and aerospace applications, where durability is crucial.

Tips: Regular maintenance of chromium-plated surfaces can enhance longevity. Use mild cleaners to avoid damaging the coating.

Chromium is also important for aesthetic purposes. Its bright, reflective finish enhances the appearance of products. Yet, producing that perfect sheen can be a challenge. Mistakes in the electroplating process can lead to dull finishes or uneven coatings. It’s essential to monitor conditions closely.

Tips: Proper ventilation and temperature control are vital for consistent quality. Always keep a detailed record of the electroplating parameters.

In conclusion, chromium holds a vital position in electroplating, balancing practicality with beauty. Its use is widespread, but attention to detail in application is critical.

Common Applications of Chromium Electroplating in Industries

Chromium electroplating is widely used across various industries due to its distinct advantages. This process enhances the surface hardness and durability of metal parts. It creates a protective layer that resists corrosion and wear. As a result, parts last longer and maintain their appeal over time. Common applications include automotive components, aerospace, and household fixtures.

In the automotive industry, chromium plating is used on bumpers and trims. These parts benefit from the shiny finish and added protection against environmental damage. Aerospace components also rely on chromium for its lightweight properties and resistance to oxidation. Additionally, in household applications, faucets and bathroom fixtures often use chrome plating for aesthetic appeal and ease of cleaning.

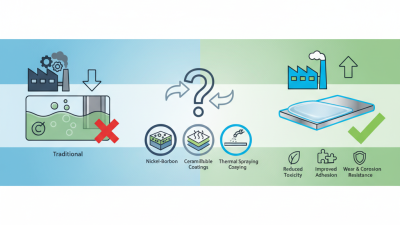

However, there are challenges with chromium electroplating. The process can produce harmful waste, raising environmental concerns. Proper waste management is essential. Not all applications require chromium’s unique properties, making it necessary to evaluate alternatives. Balancing performance and ecological responsibility is an ongoing debate in many industries.

Environmental Considerations and Safety Measures in Chromium Use

Chromium plays a significant role in electroplating, offering a shiny and protective finish. However, its environmental impact raises concerns. Chromium, especially in its hexavalent form, can be toxic. This toxicity poses risks to both human health and ecosystems. Proper management is crucial.

To mitigate these risks, safety measures must be in place. Workers should use personal protective equipment like gloves and masks. Adequate ventilation is essential in electroplating facilities. Waste disposal needs careful attention. Recycling chromium from the process can significantly reduce environmental burdens. Yet, not all facilities implement these systems.

Awareness is vital. Public discussions on chromium use can lead to better practices. The industry should strive for transparency in its operations. Continuous innovation is required to develop safer alternatives. This journey needs to address not only effectiveness but also the well-being of our planet. The balance between utility and safety is a constant challenge.

Related Posts

-

Top 10 Uses of Chromium in Electroplating You Need to Know

-

2025 How to Understand the Benefits of Chrome Plating for Your Projects

-

Why Consider Alternatives to Hard Chrome Plating for Your Industry Needs

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Why You Should Know the Different Types of Chrome Plating for Your Projects