Ultimate Tips for Black Chrome Electroplating Process and Best Practices

Black chrome electroplating is a sophisticated process that offers a unique combination of aesthetic appeal and functional advantages. As industries continue to seek solutions that enhance the durability and appearance of metal surfaces, black chrome electroplating has emerged as a popular choice. This innovative technique not only provides a striking black finish but also imparts excellent corrosion resistance and wear properties, making it ideal for a variety of applications ranging from automotive parts to decorative items.

Understanding the intricacies of the black chrome electroplating process is crucial for achieving optimal results. From surface preparation to electroplating parameters, every stage of the process requires careful attention to detail and adherence to best practices. By leveraging the right techniques and tips, practitioners can maximize the effectiveness of black chrome electroplating, ensuring high-quality finishes that meet both aesthetic and functional requirements. This comprehensive guide will delve into the ultimate tips and best practices for mastering the black chrome electroplating process, empowering professionals to achieve superior outcomes in their projects.

Understanding Black Chrome Electroplating: An Overview

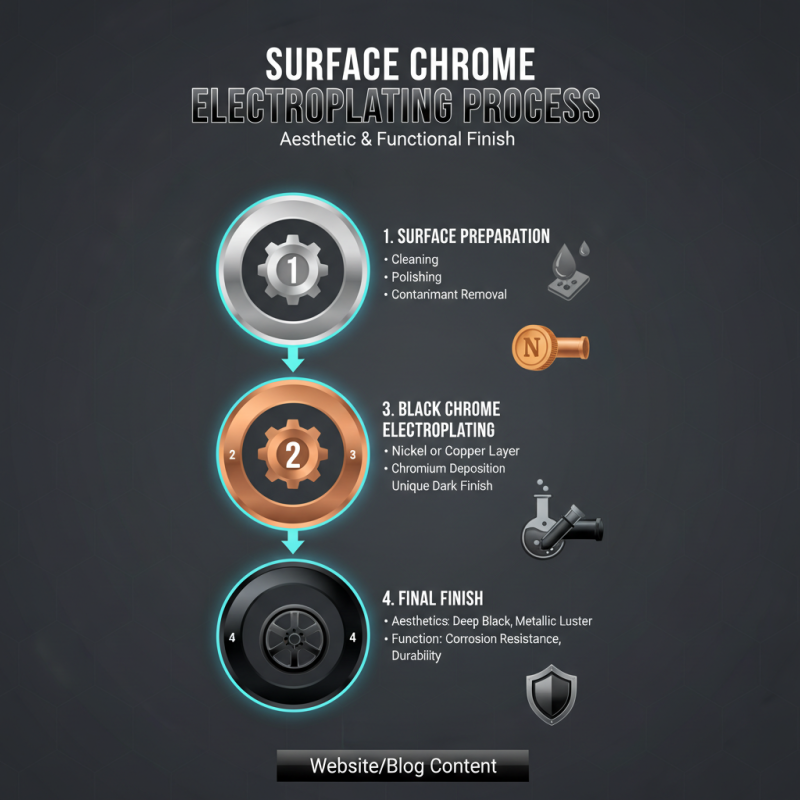

Black chrome electroplating is a sophisticated process that entails the deposition of a thin layer of chromium onto a substrate, resulting in a distinctive black finish. This technique not only provides aesthetic appeal but also enhances the durability and corrosion resistance of the coated object. The process usually begins with surface preparation, which is crucial for ensuring good adhesion and uniform coverage. This may involve cleaning, degreasing, and sometimes roughening the surface to optimize the bonding between the substrate and the plating layer.

Understanding the chemistry behind black chrome electroplating is essential for achieving consistent results. The process typically uses a bath solution containing chromium salts along with other additives that impart the desired color and finish. The electroplating conditions, such as current density, temperature, and pH levels, play a significant role in the final appearance and quality of the coating. By carefully controlling these parameters, one can produce a range of finishes from a matte black to a high-gloss effect, catering to various aesthetic and functional requirements.

Overall, mastering the black chrome electroplating technique can yield impressive results for both industrial applications and decorative purposes.

Essential Materials and Equipment for the Process

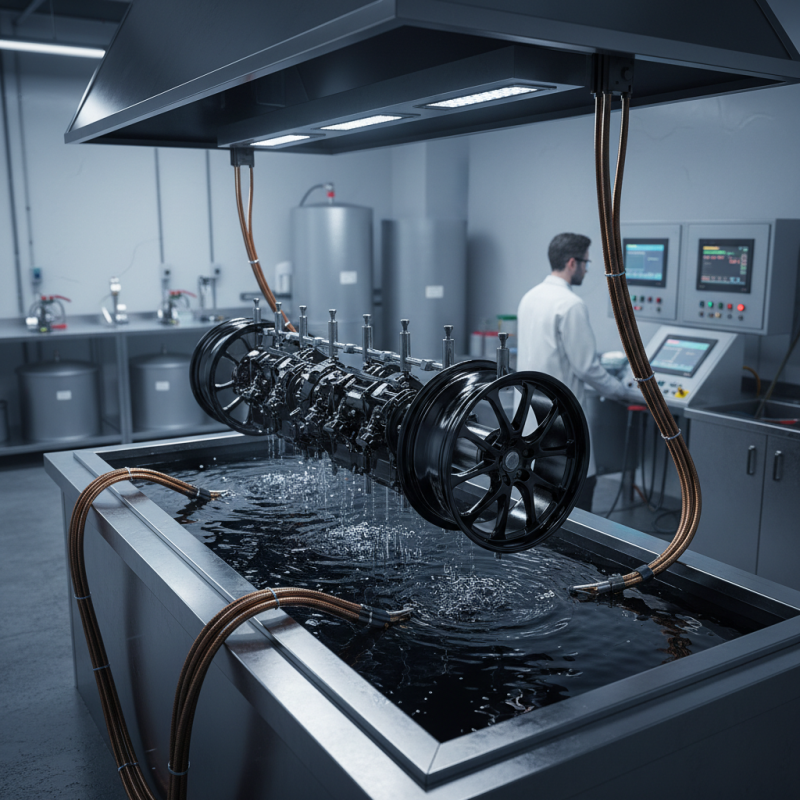

When embarking on the black chrome electroplating process, having the right materials and equipment is crucial for achieving a high-quality finish. The primary materials needed include the chrome electrolyte solution, which contains hexavalent chromium and other additives tailored for black chrome plating. Additionally, a high-purity substrate is essential, often made from metals such as steel or aluminum, to ensure proper adhesion and an even coat during plating.

Equally important are the tools and equipment necessary for the electroplating process. A reliable power supply with adjustable voltage and current is vital to maintain consistent plating conditions. You'll also need a plating tank made of a corrosion-resistant material, typically lined with polyethylene or polypropylene to withstand the harsh chemicals involved. Other essential equipment includes anode baskets, stirring mechanisms for uniform solution mixing, and safety gear such as gloves and goggles to protect against hazardous materials during the operation. With the right materials and equipment in place, the black chrome electroplating process can be executed effectively, yielding durable and aesthetically pleasing results.

Step-by-Step Guide to the Black Chrome Electroplating Procedure

The black chrome electroplating process is a unique finish that combines aesthetics with functional benefits. This process typically starts with thorough surface preparation of the substrate, which involves cleaning, polishing, and effectively removing any contaminants. A clean surface is crucial, as it ensures better adhesion of the electroplated layer. Following this, a nickel or copper layer may be applied as a base, enhancing the surface bonding for the black chrome layer.

When it comes to the plating itself, maintaining the correct bath chemistry is essential. Monitoring the temperature, pH, and current density will directly impact the quality of the final finish. In this step, it’s important to control the electroplating time for optimal thickness, as over-plating can lead to a lack of visual appeal.

**Tips:** Ensure that your workspace is free from contamination during the electroplating process. Additionally, consider conducting tests on small samples before initiating large projects to determine the desired outcome. Proper ventilation and safety equipment should not be overlooked, as this process can involve hazardous materials. Adhering to these tips will lead to the successful application of black chrome, resulting in a striking and durable finish.

Common Challenges and Troubleshooting Tips in Electroplating

Electroplating can present several challenges, particularly when applying black chrome finishes. One common issue is the inconsistent color and sheen, which can stem from improper solution chemistry or fluctuating current density. Maintaining the right pH levels and controlling temperature is crucial; even slight variations can lead to unsatisfactory results. Regularly monitoring these factors and ensuring that the plating solution is properly mixed can help achieve a uniform black chrome appearance.

Another significant challenge is the adhesion of the electroplated layer. If the surface preparation is insufficient, the coating may peel or blister. Proper cleaning and polishing of the substrate before plating are essential steps to ensure that contaminants are removed and the surface is adequately roughened for better adhesion. Additionally, troubleshooting techniques such as performing test plates can help identify potential issues early in the process, allowing for adjustments to be made before full-scale production. By understanding and addressing these common challenges, you can improve the quality and durability of your black chrome electroplating results.

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

| Aspect | Description | Common Problems | Troubleshooting Tips |

|---|---|---|---|

| Surface Preparation | Proper cleaning to remove contaminants. | Poor adhesion or visible residues. | Use ultrasonic cleaning and ensure thorough rinsing. |

| Bath Composition | Maintaining correct chemical ratios in the electroplating bath. | Inconsistent plating thickness. | Regularly test and adjust chemical concentrations. |

| Current Density | Adjusting the current applied during electroplating. | Burned or blistered surfaces. | Monitor current levels and maintain uniform distribution. |

| Temperature Control | Keeping the electroplating solution at optimal temperatures. | Poor appearance or uneven color. | Use a thermometer and heaters to regulate temperature. |

| Post-Treatment | Steps taken after plating to ensure durability. | Corrosion or wear over time. | Apply a protective coating after electroplating. |

Best Practices for Maintenance and Quality Control in Black Chrome Finishing

Maintaining high-quality standards in black chrome electroplating requires stringent practices and effective quality control measures. According to a report by the Electroplating Association, the success rate of achieving desired black chrome finishes typically hinges on precise operational parameters, including proper bath chemistry and temperature control. It’s essential to regularly monitor the concentrations of components in the plating solution, such as chromium and other additives, as fluctuations can significantly affect the coating's durability and aesthetic appeal. Regularly scheduled maintenance checks of the electroplating equipment can help ensure optimal performance, with studies indicating that 30% of failures in finishing processes are attributed to equipment malfunction.

Equally important is the implementation of inspection protocols throughout the production process. Utilizing tools such="gloss meters" and color spectrophotometers can provide quantitative data to assess the consistency and uniformity of the black chrome finish. Research published in the Journal of Coatings Technology highlights that proper surface preparation and thorough cleaning prior to electroplating can enhance adhesion and longevity of the coating, reducing the likelihood of defects such as peeling or flaking. Additionally, incorporating a robust feedback loop for quality assurance can streamline operations, with findings suggesting that companies employing structured feedback mechanisms experience a 25% decrease in production faults, leading to higher customer satisfaction and reduced rework costs.