2026 Best Industrial Chrome Plating Techniques for Enhanced Durability?

In recent years, industrial chrome plating has gained significant attention for its remarkable durability and aesthetic appeal. According to a report by MarketsandMarkets, the global chrome plating market is expected to reach $9.15 billion by 2026, indicating a steady growth driven by industries such as automotive, aerospace, and manufacturing. The rise in demand highlights the importance of adopting advanced industrial chrome plating techniques.

Despite these advancements, challenges remain. Many firms struggle with the consistency of plating quality. Variability in techniques can lead to uneven surfaces and compromised performance. The need for enhanced durability in harsh environments is evident. Research indicates that products with superior chrome plating can extend their lifespan by over 50%. Implementing improved techniques can significantly impact the longevity of components in industrial applications.

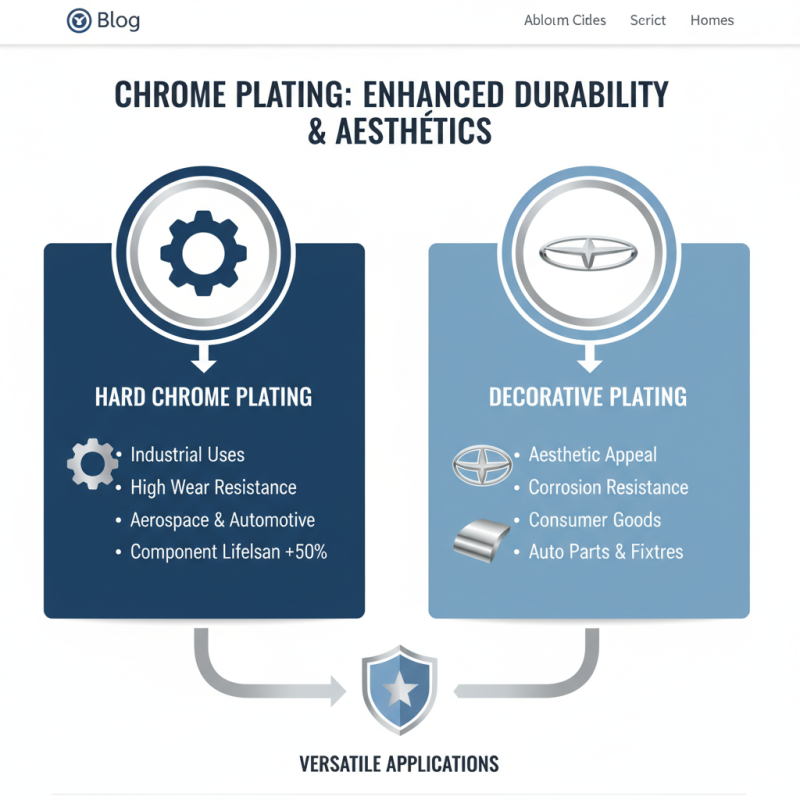

Investing in the right plating methods is essential. Techniques such as hard chrome plating and decorative chrome plating can offer enhanced resistance to wear and corrosion. However, awareness of potential shortcomings is crucial. Companies must evaluate their methods regularly. Embracing innovation in industrial chrome plating could lead to greater efficiency and sustainability in the long term.

Overview of Industrial Chrome Plating Techniques for Durability

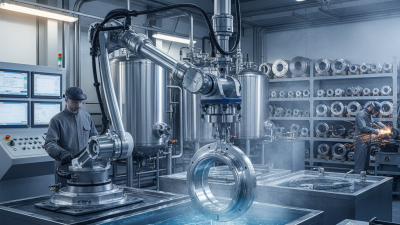

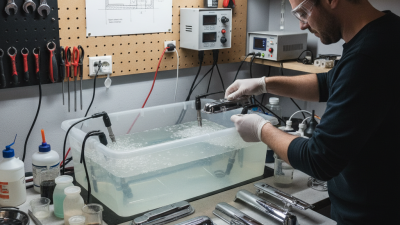

Industrial chrome plating is a key technique used to enhance the durability of various components. It provides a hard, wear-resistant surface that is crucial in demanding applications. Industry studies reveal that chrome plating can significantly improve hardness levels, often to over 1,000 HV, which is essential for parts subjected to friction and corrosion.

When considering chrome plating techniques, factors like surface preparation and plating thickness become vital. High-quality preparation ensures better adhesion. However, many operators overlook this crucial step, leading to premature failures. The thickness of the chrome layer also affects longevity. A layer around 0.5 to 1 mil is typical, influencing the component's wear resistance.

**Tips:** Always inspect substrates before plating. This can prevent future wear issues.

Environmental considerations are essential too. Chrome plating often involves chemicals that can affect ecosystems if not managed correctly. Many industries are looking for sustainable alternatives, but transition processes can be slow. Keeping abreast of regulatory changes and innovations is essential for a successful shift.

**Tips:** Invest in training for staff on eco-friendly techniques.

In conclusion, while chrome plating offers substantial benefits, careful attention to technique and environmental impact is necessary to achieve optimal results.

Types of Chrome Plating Processes and Their Applications

Chrome plating is a widely used process in various industries due to its ability to enhance durability and aesthetic appearance. There are several types of chrome plating processes, each suited for specific applications. The two primary methods are hard chrome plating and decorative chrome plating. Hard chrome plating is favored in industries that demand high wear resistance, such as aerospace and automotive sectors. According to a recent industry report, hard chrome plating can increase component lifespan by up to 50%.

Decorative chrome plating is often used for items like automotive trim and household fixtures. This process provides a shiny finish while also protecting underlying materials from corrosion. However, it lacks the hardness of hard chrome plating. The thickness of the layer affects durability significantly; a thicker layer generally offers better protection. A study indicated that decorative chrome plating typically has a thickness of 0.2 to 0.5 microns, which may not suffice for heavy wear applications.

While chrome plating can enhance product life, it is not without challenges. The process requires stringent environmental controls to manage hazardous waste and chemicals. Inadequate control can lead to environmental damage. Some companies struggle to meet regulatory standards, risking costly fines and damage to reputation. This highlights the need for industries to adopt cleaner technologies while maintaining product quality.

Factors Influencing the Quality of Chrome Plating

The quality of chrome plating is influenced by several critical factors. One significant element is the surface preparation of the substrate. A clean and properly prepared surface helps the chrome adhere effectively. Reports indicate that poorly prepared surfaces can lead to diminished adhesion and uneven finishes. It results in costly rework and, in some cases, component failure.

Another essential factor is the thickness of the chrome layer. Industry standards suggest a minimum thickness of 0.5 microns for durability, while high-performance applications may require layers exceeding 1 micron. However, thicker layers can introduce other complexities, such as cracking or peeling. It's vital to balance thickness with practical implications.

Additionally, the electroplating process itself plays a crucial role. Electrolyte composition, current density, and plating time all affect the quality. For instance, variations in current density can lead to inconsistent deposit quality. Data shows that controlling these parameters is essential for achieving an even and high-quality finish. Regular monitoring and adjustment may be needed, as human error can impact the overall output. Each of these factors highlights the importance of a comprehensive approach to chrome plating that considers preparation, application, and quality control.

2026 Best Industrial Chrome Plating Techniques for Enhanced Durability

This chart illustrates the effectiveness of various chrome plating techniques in enhancing durability. The data reflects the corrosion resistance, wear resistance, and overall finish quality of different methods used in industrial chrome plating.

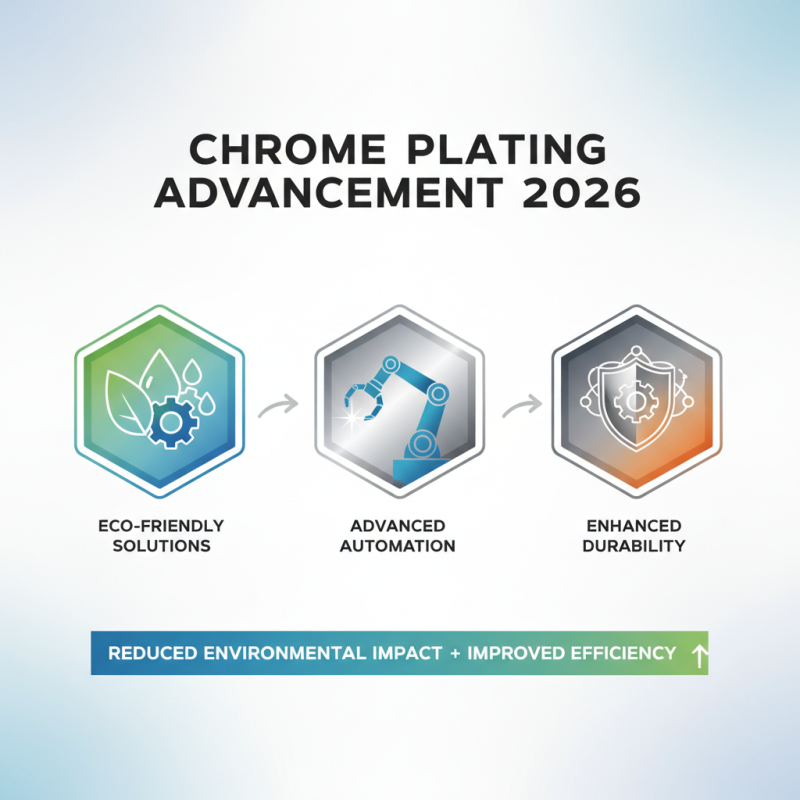

Emerging Trends in Chrome Plating Technologies for 2026

The year 2026 is set to bring exciting advancements in chrome plating technologies. As industries strive for enhanced durability, innovative techniques are emerging. Recent developments include eco-friendly plating solutions and advanced automation. These trends focus on reducing environmental impact while improving efficiency.

One area gaining traction is the introduction of nanotechnology. This approach enhances the surface properties of chrome, making it more resistant to wear and corrosion. Additionally, improved bonding agents are being utilized. They ensure better adhesion of chrome to various substrates, increasing the longevity of the coating.

**Tips:** When selecting a chrome plating service, consider the environmental practices of the provider. Look for certifications that ensure sustainable practices. Asking how they handle waste can give insight into their commitment to green technologies. Regular maintenance of plated items can also extend their lifespan, so factor this into your usage plans.

Maintenance and Quality Control in Chrome Plating Operations

In chrome plating operations, maintenance is essential for achieving enhanced durability. Regular inspections can detect early signs of wear. Operators should check equipment and replace worn-out parts promptly. This not only extends the life of the plating but also ensures consistent quality.

Tips: Create a maintenance schedule for your equipment. This will help in planning checks and avoid unexpected downtime. Keep a log of maintenance activities. It provides insights into recurring issues.

Quality control is equally critical. Consistent monitoring of the plating thickness is vital. Variations can lead to premature failure. Routine sampling of plated items can catch defects early. Proper training for staff ensures everyone understands quality standards.

Tips: Use a checklist for quality inspections. This helps in maintaining uniform standards. Encourage feedback from the team on the plating process. Their insights can lead to improvements.

Related Posts

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Top 10 Tips for Successful DIY Chrome Plating at Home

-

What is Decorative Plating and How Does it Enhance Product Aesthetics