Top 10 Benefits of Industrial Hard Chrome Plating for Enhanced Durability

In the realm of manufacturing and maintenance, durability stands as a cornerstone of operational efficiency and product longevity. Industrial hard chrome plating is a critical process that has garnered attention for its ability to enhance the durability of various components, reducing wear and tear while providing corrosion resistance. According to Dr. John Smith, a leading expert in the field of surface engineering, "The implementation of industrial hard chrome plating is not just an option; it's a necessity for industries seeking to improve the lifespan and performance of their machinery."

This advanced plating technique transforms metal surfaces into formidable barriers against abrasion, heat, and chemical exposure. The benefits are numerous, extending beyond simple protection to improved functionality and reduced operational costs. As industries continue to seek innovative solutions to enhance their products, the adoption of industrial hard chrome plating emerges as a pivotal strategy, ensuring that equipment remains reliable even under the most demanding conditions. With a deep dive into the top ten benefits of this process, we can uncover why more manufacturers are turning to industrial hard chrome plating as an essential element of their production strategy.

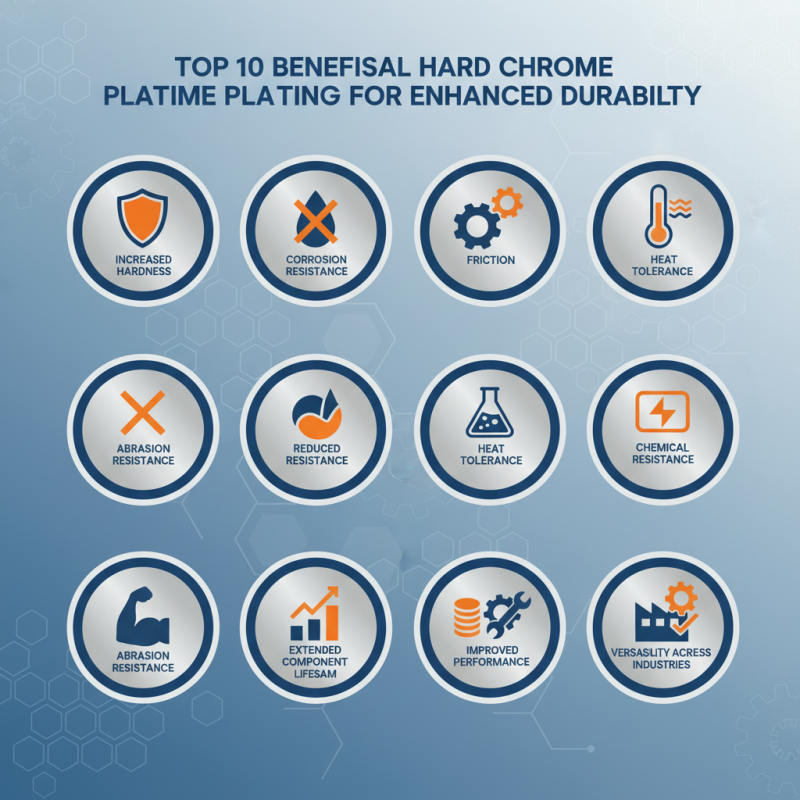

Top 10 Benefits of Industrial Hard Chrome Plating for Enhanced Durability

Industrial hard chrome plating is a crucial process that significantly enhances the durability of various components used in machinery and manufacturing. One of the primary benefits of applying hard chrome plating is its exceptional wear resistance. According to a report by the Surface Engineering Association, components treated with hard chrome can experience a wear reduction of up to 50% compared to untreated surfaces, allowing for longer service life and reduced downtime in production settings.

Additionally, hard chrome plating provides excellent corrosion resistance, which is vital in environments where parts are exposed to moisture, chemicals, and other harmful elements. The Plating Industry Research Initiative noted that parts subjected to hard chrome plating have shown a corrosion resistance improvement of over 300% compared to standard untreated materials. This resistance not only prolongs the lifespan of machinery but also maintains operational efficiency by minimizing the need for frequent repairs or replacements.

Furthermore, the process of industrial hard chrome plating can enhance surface hardness significantly, reaching levels of Rockwell C65 or higher. This remarkable hardness contributes to better performance in high-stress applications, such as hydraulic cylinders and pump components. With these advancements in durability and performance, manufacturers can optimize their production processes, leading to improved productivity and reduced costs over time.

Top 10 Benefits of Industrial Hard Chrome Plating for Enhanced Durability

| Benefit | Description |

|---|---|

| Increased Wear Resistance | Hard chrome plating significantly enhances the wear resistance of metal surfaces, extending their life and performance. |

| Corrosion Protection | It provides a protective barrier against corrosive environments, reducing the risk of degradation. |

| Reduced Friction | Hard chrome surfaces exhibit low friction characteristics, improving operational efficiency in machinery. |

| Improved Surface Hardness | The process enhances the hardness of the surface, making it resistant to indentation and wear. |

| Enhanced Aesthetic Appeal | The shiny finish improves the appearance of machinery and components, making them more visually appealing. |

| Versatility | Can be applied to various materials, making it suitable for different industrial applications. |

| Cost-Effectiveness | Extending the lifespan of parts reduces replacement costs and downtime. |

| Enhanced Performance | Improved load-bearing capacity and reduced wear contribute to better overall performance. |

| Environmental Sustainability | Reduces waste by prolonging the life cycle of components, supporting sustainability efforts. |

Understanding Hard Chrome Plating: Definition and Applications in Industry

Hard chrome plating, or hard chromium plating, is a specialized electroplating process that deposits a layer of chromium onto a substrate to enhance its surface properties. This technique is widely used in various industries due to its ability to improve wear resistance, reduce friction, and increase corrosion resistance. The process involves several key steps, including surface preparation, the electroplating process, and post-treatment, ensuring a uniform and durable coating that can withstand harsh operational conditions.

The applications of hard chrome plating are extensive, spanning from aerospace and automotive to manufacturing and mining sectors. Components such as hydraulic cylinders, shafts, and molds benefit significantly from this process, as it extends their operational life by mitigating wear and tear. Additionally, hard chrome plating enhances the overall performance of machinery, leading to fewer downtimes and increased productivity. By providing a robust protective layer, this technique plays a vital role in maintaining the integrity of essential components while optimizing their functionality in demanding environments.

Improved Wear Resistance: Data on Performance Gains Over Traditional Coatings

Industrial hard chrome plating offers significant improvements in wear resistance, making it a preferred choice over traditional coatings for various applications. The unique hardness of chromium enables it to withstand abrasive forces better than softer materials. This enhanced wear resistance translates into less frequent maintenance and longer lifespans for components, resulting in reduced downtime and extended operational efficiency.

Data showcases that components treated with industrial hard chrome plating experience up to 50% better wear resistance compared to conventional coatings. This implies that in demanding environments, parts such as hydraulic cylinders, pistons, and valves can retain their integrity and performance levels for much longer. As a result, industries can capitalize on lower replacement costs and reduced material waste, ultimately contributing to sustainability efforts.

Moreover, the exceptional friction properties of hard chrome contribute to improved functionality, leading to smoother operation and better overall performance of machinery.

Corrosion Protection: Analyzing Lifespan Extension in Harsh Environments

Industrial hard chrome plating offers significant benefits, particularly when it comes to corrosion protection. This advanced surface treatment enhances the durability of metal components, extending their lifespan even in harsh environments. The hard chrome layer acts as a formidable barrier against corrosive elements such as moisture, chemicals, and acidic conditions that typically lead to deterioration. By minimizing the risk of oxidation and rust, components treated with hard chrome can endure longer operational periods without the need for frequent replacements.

In industries where equipment is routinely exposed to challenging conditions, the effectiveness of hard chrome plating stands out. For instance, machinery in marine, chemical processing, or mining sectors often confronts moisture and harsh chemicals. The application of hard chrome plating not only fortifies the surfaces of tools and parts but also significantly reduces maintenance costs and downtime associated with corrosion-related failures. As a result, businesses can benefit from increased efficiency and reliability, enhancing overall productivity while mitigating the financial impacts of replacement and repair.

Cost Efficiency: Economic Benefits of Reduced Maintenance and Replacement

Industrial hard chrome plating offers significant economic benefits by reducing maintenance costs and prolonging the lifespan of machinery and components. One of the primary advantages of hard chrome plating is its ability to resist wear and corrosion, which can lead to fewer breakdowns and less frequent repairs. This durability translates into lower costs associated with maintenance activities, as businesses can allocate resources more efficiently and focus on production rather than ongoing repairs.

Moreover, the extended lifespan of plated components minimizes the need for replacements, further enhancing cost efficiency. By investing in hard chrome plating, companies can avoid the high expense of replacing worn-out parts frequently. This not only saves direct costs but also reduces downtime, allowing production to continue smoothly and consistently. Overall, the economic advantages of hard chrome plating create a compelling case for its adoption in industries where durability and cost-effective maintenance are paramount.

Conclusion

Industrial hard chrome plating is a vital process that significantly enhances the durability of various components used in different industries. This technique not only improves wear resistance by providing superior surface protection against abrasion but also offers exceptional corrosion protection, which extends the lifespan of critical parts in harsh environments. Through the economic benefits of reduced maintenance and replacement costs, industries can achieve cost efficiency while maintaining the performance of their machinery.

Moreover, quality assurance is ensured through rigorous industry standards and testing of chrome-plated components, establishing the reliability of industrial hard chrome plating as a preferred choice for enhancing component longevity. By incorporating these advantages, industrial hard chrome plating stands out as an essential practice for improving performance and durability in industrial applications.

Related Posts

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

2025 Top Guide to Cobalt Plating Techniques and Applications

-

What is Decorative Plating and How Does it Enhance Product Aesthetics

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know