How to Achieve Perfect Copper Chrome Plating Results?

Copper chrome plating has become essential in various industries, primarily due to its excellent corrosion resistance and aesthetic appeal. According to a report by Grand View Research, the global electroplating market is expected to reach USD 22.4 billion by 2027, with copper chrome plating being a significant contributor to that growth. This plating process not only enhances the durability of components but also improves their surface finish.

Achieving perfect copper chrome plating results is not an easy task. Several factors, such as the quality of the base material and plating bath parameters, play a significant role. A study published in "Surface Engineering" highlights that a mere 5-degree fluctuation in temperature can lead to inconsistent plating thickness. Addressing these variables requires meticulous control and often involves trial and error, which can be frustrating yet crucial for achieving desired outcomes.

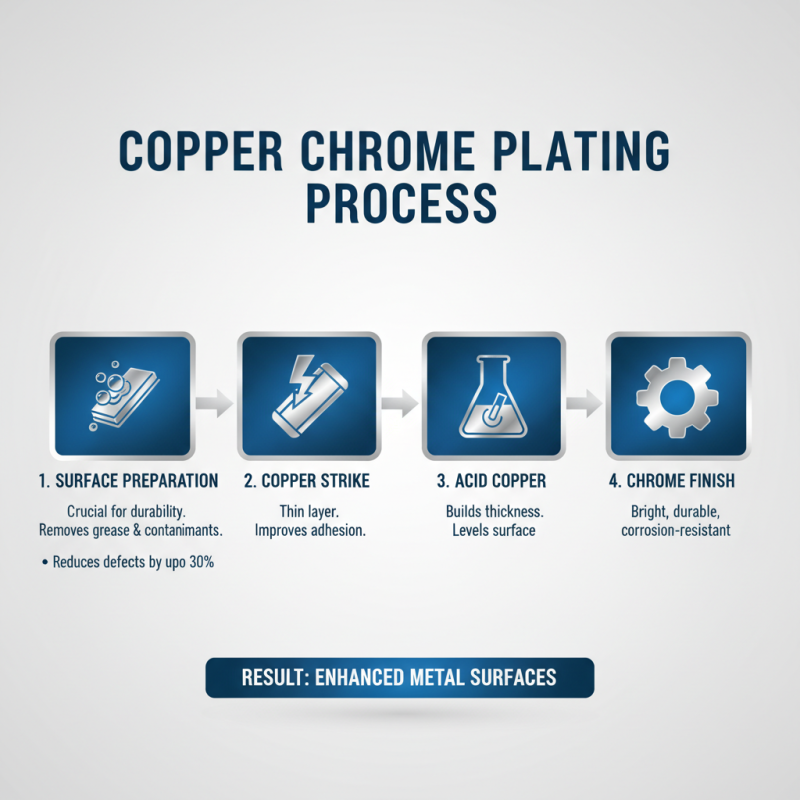

Moreover, there are often overlooked challenges in the copper chrome plating process. Issues like poor adhesion and surface defects can compromise the integrity of the plating. According to the American Electroplaters and Surface Finishers Society, up to 30% of plated parts can exhibit defects. This calls for a more reflective approach to the plating procedure, urging manufacturers to continuously improve methods for success.

Understanding Copper Chrome Plating: Materials and Equipment Needed

Copper chrome plating is a specialized process requiring specific materials and equipment. Key components include high-purity copper and chromium solutions. The quality of these materials can significantly impact the plating outcome. For instance, studies indicate that impurities in the copper solution can lead to poor adhesion and reduced durability. It's crucial to source your materials from reliable suppliers to ensure optimal results.

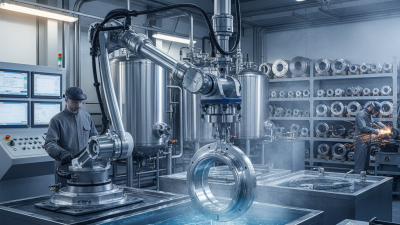

You'll also need several tools and equipment to perform the plating effectively. A high-quality plating bath, precise temperature control systems, and advanced rectifiers are essential for achieving uniform deposits. According to a recent industry report, over 70% of plating defects occur due to inadequate control of these variables. Proper maintenance of your equipment is vital to avoid inconsistencies.

However, challenges may arise during the process. Inadequate preparation of the substrate can lead to defects such as pitting or blistering. Improper voltage settings may cause uneven deposits, which can affect aesthetics and functionality. Regular inspection and adjustment are necessary to prevent these issues. Each step of copper chrome plating demands careful attention to detail, and overlooking any aspect can lead to less than perfect results.

Preparing Your Surface: Cleaning and Pre-treatment Techniques

Achieving perfect copper chrome plating begins long before the electroplating process. It’s essential to focus on surface preparation. Cleaning the surface thoroughly is the first crucial step. Any dirt, grease, or oxidation can compromise the final finish. Use a specialized cleaner to remove these contaminants. A simple cloth may not reach every crevice, so consider ultrasonic cleaning for more intricate shapes. This can enhance the overall quality.

Once cleaned, pre-treatment is next. This step often requires an acidic bath to etch the surface. However, be cautious. Over-etching can damage the material, so monitor the duration closely. Rinsing afterward is vital. Any residual acid can adversely affect adhesion.

After pre-treatment, inspect the surface. Look for imperfections like scratches or pits that could lead to plating failures. Treat these flaws carefully, as they will become more pronounced after plating. Sometimes, despite following all steps, the result might still be uneven. This could be due to inadequate cleaning or improper angles during plating. Reflecting on these points can guide improvements for future tasks.

The Plating Process: Step-by-Step Guide to Copper Chrome Application

Copper chrome plating is a process that enhances metal surfaces with a bright, durable finish. The application involves several crucial steps. First, proper surface preparation is vital. This includes cleaning to remove grease and contaminants. A study found that up to 30% of plating imperfections arise from inadequate cleaning. A thorough cleaning process can significantly reduce these defects.

Next, the actual plating process begins. The metal is immersed in an electrolytic bath containing copper and chromium. Monitoring bath temperatures is essential. According to industry reports, maintaining the right temperature can improve deposition rates by 25%. However, inconsistent temperatures can lead to uneven coatings, which compromise the final finish.

After the plating, parts need to undergo post-treatment processes, such as polishing and inspection. Approximately 15% of finished products often require reworking due to surface flaws. Regular inspections during each phase can mitigate this waste. Ensuring thorough quality checks helps to identify issues early on. The process requires diligence and attention to detail to achieve the desired results.

Post-Plating Care: Techniques for Achieving a Durable Finish

Post-plating care is crucial for achieving a durable finish in copper chrome plating. After the plating process, it's essential to ensure that the surface is clean and free from contaminants. Even tiny specks of dust can compromise the finish. Gently rinse the plated item with distilled water to remove residual chemicals. This step should never be skipped.

Next, consider applying a protective coating. A clear sealant can enhance the shine and provide additional protection against oxidation. However, not all coatings are equal, and finding the right one can be challenging. Some might yellow over time, while others may not adhere properly. This process requires trial and error to determine the best fit for your materials.

Regular maintenance is also important. Aim to clean the plated surface with a soft cloth regularly. Avoid abrasive materials that might scratch the surface. If tarnishing occurs, use a gentle cleaner designed for plated surfaces. Remember, while copper chrome plating can offer a stunning finish, neglecting proper care can lead to rapid deterioration. Pay attention to the details; they often define the longevity of your work.

Common Challenges and Solutions in Copper Chrome Plating

Copper chrome plating can enhance the appearance and durability of metal components. However, achieving perfect results comes with its own set of challenges. One common issue is uneven coating. This often occurs due to improper surface preparation. If the metal is not cleaned thoroughly, areas may not receive the necessary layers of plating. It's vital to ensure surfaces are free of dirt and oil.

Another challenge is the risk of pitting. Pitting can arise from contamination of the plating bath. Impurities can lead to defects that ruin the aesthetic and functional quality of the finish. Regular monitoring of the plating solution is essential. Adjusting chemical concentrations can mitigate these effects. Recognizing signs of pitting early on can save time and resources.

Thickness of the plating is another concern. Achieving the right thickness is crucial for durability. Inconsistent plating can cause weak spots. This could result in premature wear or failure under stress. Regular testing of coated samples can help maintain quality. Each plating process should be reviewed to ensure consistency in results. Embracing these challenges helps improve the overall quality of copper chrome plating.

How to Achieve Perfect Copper Chrome Plating Results? - Common Challenges and Solutions in Copper Chrome Plating

| Challenge | Description | Solution |

|---|---|---|

| Poor Adhesion | The copper layer does not adhere well to the substrate, leading to peeling. | Ensure proper surface preparation and cleaning before plating. |

| Uneven Thickness | The plated layer is not uniform, resulting in poor appearance and durability. | Control current density and maintain consistent plating parameters. |

| Black Spots | Dark discolorations appear on the surface of plated items. | Optimize bath chemistry and ensure filtration is effective. |

| Bubbles and Pinholes | Gas bubbles trapped under the plating layer lead to pinholes. | Use deaeration techniques and optimize the plating solution agitation. |

| Color Variation | Different shades of chrome appear on the same piece. | Maintain a consistent temperature and mixing in the plating solution. |

Related Posts

-

2025 How to Understand the Benefits of Chrome Plating for Your Projects

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

2025 Top Guide to Cobalt Plating Techniques and Applications

-

Top 10 Uses of Chromium in Electroplating You Need to Know

-

How is Chromium Used in Electroplating? Advantages and Applications Explained

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know