2025 Top Industrial Chrome Plating Techniques Benefits and Applications

Industrial chrome plating has emerged as a critical technology in various manufacturing sectors due to its exceptional properties that enhance the performance and durability of components. According to a report published by MarketsandMarkets, the industrial chrome plating market is projected to reach $4.5 billion by 2025, driven by the increasing demand for efficient and durable surface coatings in industries such as automotive, aerospace, and machinery. This robust growth illustrates the importance of improving product lifespan and performance through advanced plating techniques.

Experts in the field emphasize the multifaceted benefits of industrial chrome plating. Dr. Samuel Hayes, a noted authority in surface engineering, states, "The right chrome plating techniques not only improve corrosion resistance and wear properties but also enhance the aesthetic appeal of products." As more industries recognize these advantages, they are increasingly adopting innovative plating techniques that leverage the latest technology, thereby enabling enhanced operational efficiency, reduced maintenance costs, and sustainable practices.

With the advancements in industrial chrome plating techniques, businesses are better positioned to meet the evolving demands of their markets. This article delves into the top chrome plating techniques of 2025, highlighting their benefits and applications across various industries, ensuring that businesses stay competitive and efficient in a rapidly changing economic landscape.

Overview of Industrial Chrome Plating Techniques and Their Evolution

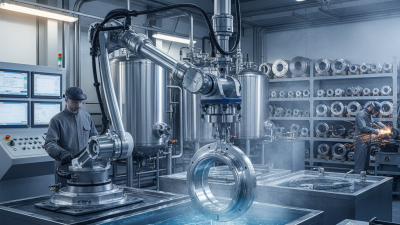

Industrial chrome plating has undergone significant evolution over the years, becoming an essential process in various industries. Initially developed for decorative purposes, techniques have expanded to include hard chrome plating, which enhances wear resistance and corrosion protection. The introduction of advanced electroplating methods has allowed for greater control over the coating thickness and quality, leading to improved performance characteristics. Recent developments, such as the use of environmentally friendly chemicals and the implementation of automation, have further optimized production efficiency and reduced environmental impact.

Tips: When considering chrome plating techniques, industries should assess their specific needs—such as the desired finish, application, and durability requirements. This comprehensive approach ensures that the selected plating method aligns with both performance expectations and sustainability goals.

As the technology continues to advance, it is crucial for manufacturers to stay informed about emerging techniques. Innovations like laser-assisted plating and the use of nanotechnology are paving the way for even more efficient methods that can provide superior results. Exploring these options can lead to significant competitive advantages in the marketplace.

Tips: Regular training and updates for staff on the latest chrome plating technologies can enhance overall productivity and product quality. Engaging with industry forums and workshops can also provide valuable insights into future trends and techniques.

Benefits of Chrome Plating: Enhancing Durability and Corrosion Resistance

Chrome plating is a widely adopted technique in various industries, offering significant benefits in terms of durability and corrosion resistance. One of the primary advantages of chrome plating is its ability to enhance the longevity of metal parts. The chrome layer acts as a protective barrier that resists wear, effectively reducing the impact of friction during operation. This is particularly beneficial for components subjected to high-stress conditions, ensuring they maintain their functionality over time.

Moreover, the corrosion-resistant properties of chrome plating are crucial for many applications. By forming a dense, hard surface, chrome plating prevents moisture and other corrosive agents from penetrating the underlying metal. This feature is especially valuable for parts exposed to harsh environments, including automotive and industrial applications, where components face continual exposure to environmental elements. Additionally, the shiny, aesthetic finish of chrome plating makes it an appealing choice for decorative applications, combining practicality with visual enhancement. Overall, chrome plating stands out as a reliable method for improving the performance and lifespan of metal components across various sectors.

2025 Top Industrial Chrome Plating Techniques Benefits and Applications

| Technique | Benefit | Application | Durability | Corrosion Resistance |

|---|---|---|---|---|

| Electroplating | High gloss finish | Automotive components | Excellent | Good |

| Electroless Plating | Uniform thickness | Electrical connectors | Good | Excellent |

| Hard Chrome Plating | Increased wear resistance | Hydraulic cylinders | Excellent | Good |

| Chromic Acid Anodization | Enhanced adhesion | Aerospace components | Good | Excellent |

| Chrome Plating on Plastic | Lightweight and aesthetic | Consumer electronics | Moderate | Good |

Applications of Chrome Plating in Automotive and Aerospace Industries

In the automotive and aerospace industries, chrome plating plays a crucial role in enhancing the durability and aesthetic appeal of components. According to a report by MarketsandMarkets, the global chrome plating market is projected to reach USD 8.65 billion by 2025, driven by the booming automotive sector, which alone represents a significant portion of the demand due to chrome's excellent corrosion resistance and surface hardness. The ability of chrome plating to provide a shiny finish not only improves the visual appeal but also contributes to wear resistance, making it ideal for parts such as bumpers, wheels, and engine components.

In aerospace applications, chrome plating is integral to ensuring that components withstand harsh environmental conditions and the rigors of flight. The Aerospace Industries Association highlights that components like landing gears and turbine engines benefit extensively from chrome plating due to its capacity to reduce friction and improve overall performance. Chrome plating's smooth surface minimizes drag, which is critical in achieving fuel efficiency, thereby aligning with the industry's push towards sustainability and reduced emissions. As innovations in chrome plating techniques continue to evolve, the benefits for both automotive and aerospace sectors are set to enhance even further, solidifying chrome plating's position as a staple in high-performance engineering.

Environmental Considerations and Regulations Impacting Chrome Plating

Environmental considerations play a crucial role in the chrome plating industry, particularly as regulations evolve to address environmental impact. The chrome plating process has historically posed concerns due to the use of hexavalent chromium, a known carcinogen. According to the U.S. Environmental Protection Agency (EPA), the introduction of stringent regulations has been essential in minimizing the hazardous effects associated with chrome plating. These regulations often require strict emissions controls and wastewater management practices to protect air and water quality.

Recent industry reports indicate that advancements in technology have led to the development of trivalent chromium plating processes, which significantly reduce the environmental footprint compared to traditional hexavalent methods. A 2022 study published by the National Association for Surface Finishing highlighted that trivalent plating not only offers enhanced safety but also provides comparable plating quality and durability. Moreover, companies adopting these new techniques have been able to reduce their regulatory burdens and associated costs, resulting in greater competitiveness and sustainability.

As consumers and industries increasingly prioritize sustainability, chrome plating facilities are recognizing the necessity of compliance with environmental regulations not just as a legal obligation but as a pathway to enhance their market position. Adopting environmentally friendly practices, such as recycling wastewater and utilizing green chemicals, can yield not only regulatory compliance but also a positive corporate image, driving growth in a market increasingly influenced by sustainability parameters.

Future Trends in Chrome Plating Technologies and Innovations by 2025

As we approach 2025, the landscape of chrome plating technologies is set to undergo significant transformations driven by advancements in materials science and engineering practices. One prominent trend is the integration of environmentally friendly techniques that minimize the use of hazardous substances in chrome plating processes.

Innovations such as trivalent chrome plating are gaining traction, not only for their reduced toxicity but also for their ability to deliver high-quality finishes comparable to traditional hexavalent chrome. This shift reflects an increasing commitment to sustainability within the industry and a response to regulatory pressures aimed at reducing environmental impact.

Another emerging trend in the chrome plating sector is the incorporation of automation and smart technologies. The use of artificial intelligence and machine learning algorithms in process control is expected to enhance the efficiency and precision of chrome plating applications. This can lead to reduced operational costs and improved consistency in product quality.

Additionally, the development of advanced surface preparation techniques, such as micro-sandblasting and laser treatments, is anticipated to further enhance adhesion and performance of the chrome finishes. As these innovations move forward, they promise to redefine the capabilities and applications of chrome plating in various sectors, including automotive, aerospace, and consumer goods.

Related Posts

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

Top 10 Benefits of Industrial Hard Chrome Plating for Enhanced Durability

-

Ultimate Tips for Black Chrome Electroplating Process and Best Practices

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

10 Essential Tips for Successful Industrial Chrome Plating You Need to Know